The companies have been working together on the technique since 2010 and the details have been released by Siemens in its January 2017 media circular, although the YouTube video used here is dated 10 November, 2014, and the punch-tap brochure download at Emuge-Franken's special website is dated August 2014. In fact, the product looks first to have been unveiled at Germany's AMB 2014 exhibition.

According to Emuge-Franken's special punch-tap website, the tool is only being used by the Audi plant in Györ, Hungary. There is no mention made of punch-tap on Emuge-Franken's main website, incidentally.

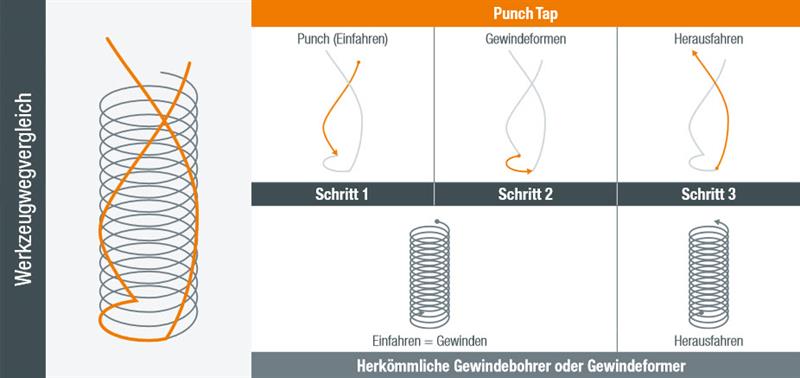

As the technique's name suggests, it combines punching and threading. Requiring development of a tool, special toolholder and a CNC cycle to employ it, the process entails driving the specially designed punch-tap tool, which has two twisted and offset rows of teeth, into a pre-drilled hole, employing a helical movement while doing so, achieving this in a fraction of a second.

With two helical grooves thus generated, the spindle then turns by 180° while the axial feed axis is simultaneously retracted by half a thread pitch to complete machining of the thread. The special tool is then withdrawn helically.

A diagrammatic representation of the movement of the punch-tap tool

Siemens personnel from the company’s Technology and Application Center (TAC) in Erlangen, Germany, undertook a simulated analysis of the requirements that must be fulfilled by a machine tool for the punch-tap process to be safely employed.

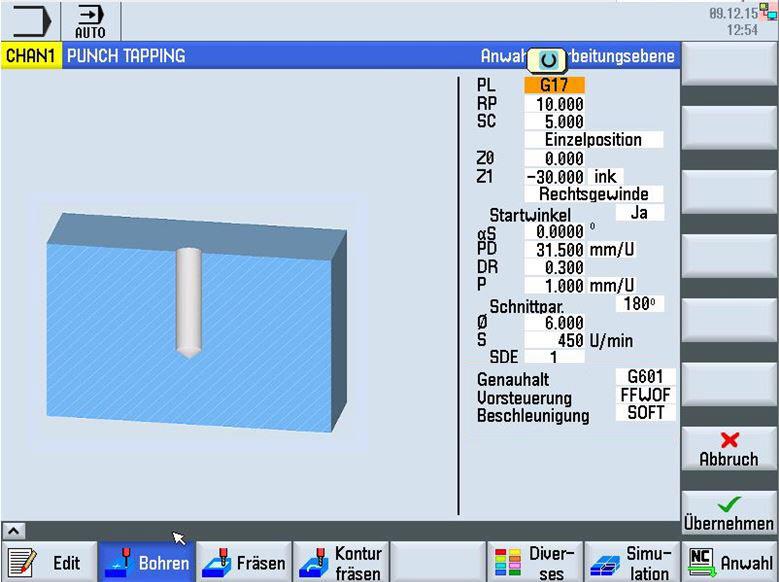

The punch-tap CNC cycle is available for Sinumerik 840D sl and Sinumerik 828D controls, both for the latest generation V4.7 and as a subsequent upgrade for Version V4.5. The cycle is used with Sinumerik Operate. All the operator has to do is open the G-code programming system Sinumerik programGuide and enter the required coordinates. Guided by the menu, pressing just a few buttons is all that is needed to set the required degree of twist and the reversal point.

The punch-tap Siemens CNC cycle asks for various data to be entered

For more details, visit Emuge-Franken's special punch-tap website, link below; a link to a full technical article penned by Emuge-Franken and Audi personnel is also below