The quick-change system can be retrofitted onto every three-jaw chuck of size 200, 250/260, 315, and various two-, four- and six-jaw chucks.

The system comprises three types of base jaw, for small, medium or large parts, over which a number of styles of working jaws can be slid and secured, using a single screw per jaw to effect unclamping and clamping. In the locked condition, a six-sided form-fit locking ensures maximum process stability and allows a high force and torque transmission.

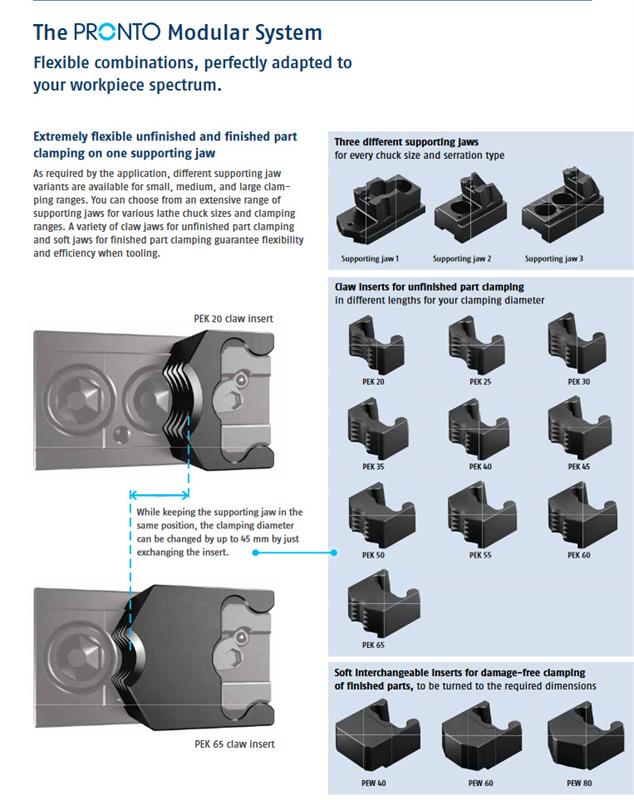

There are 10 so-called claw working jaws for clamping raw parts, with three types of soft jaw available for holding on finished surfaces. They can be used with any base jaw. Within the claw jaw range, a clamping diameter variation of 45 mm can be accommodated.

Users can mill customised contours into the soft jaws or, alternatively, jaws can be machined and delivered by Schunk on short notice.

Repeat accuracy of 0.02 mm reduces the need to rebore jaws, with turned or milled clamping inserts used again.

There is a set-up cart is available that ensures clean storage and fast access to claw inserts, soft inserts, supporting jaws, screws, T-nuts and adjustment aids. On-machine storage is additionally available.

See image below for more detail and visit the link below that to view the whole PDF catalogue.