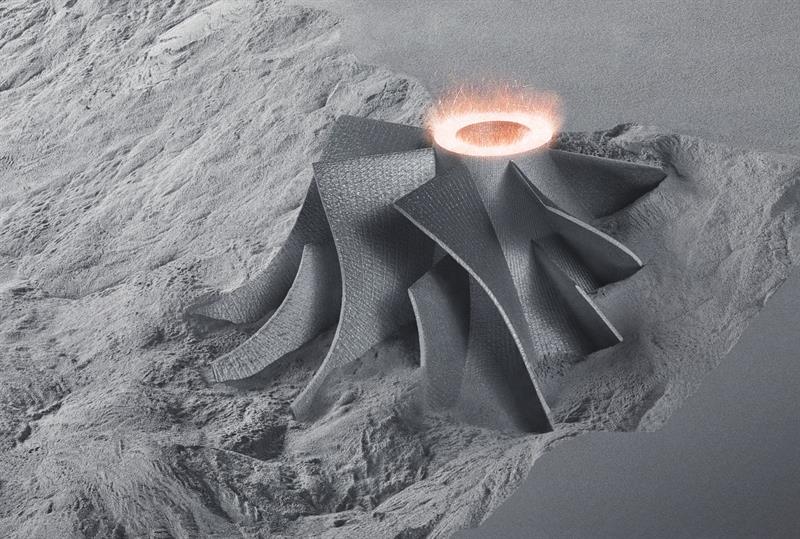

Both laser metal fusion (LMF) and laser metal deposition (LMD) machines will be on display. LMF systems generate parts layer by layer in a bed of powder and are appropriate for parts that are geometrically complicated and extremely elaborate.

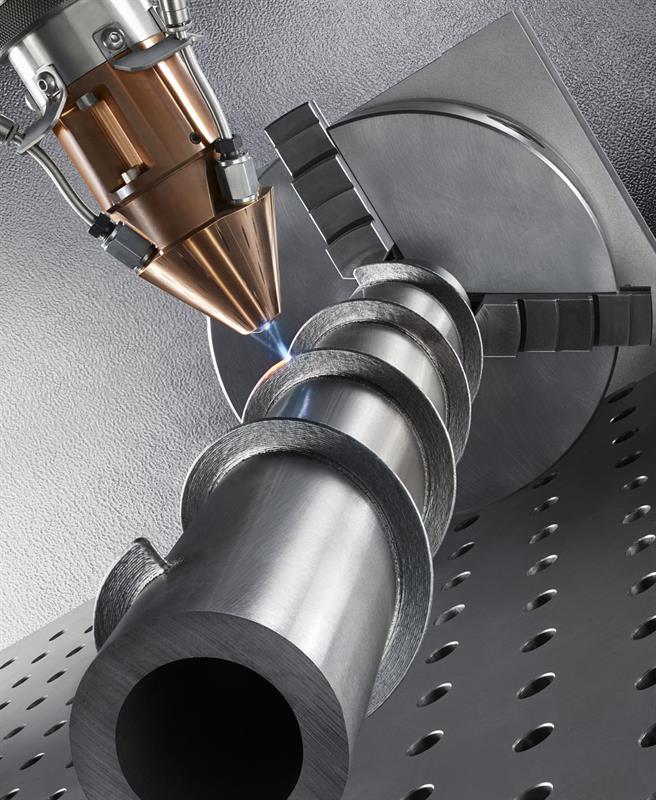

In LMD systems, a laser creates a melted pool on the surface of a part and fuses powder that is added simultaneously in a powder stream to achieve the desired shape. LMD can, at high processing speed, add closely defined structures to existing tools and components.

Laser metal fusion generates parts layer by layer in a bed of powder and is appropriate for parts that are geometrically complicated and extremely elaborate

Laser metal deposition fuses powder that is added simultaneously in a powder stream

Explains Dr Ing Eh Peter Leibinger, head of Trumpf Laser- und Systemtechnik GmbH: “LMF and LMD are the two leading technologies in the additive manufacture of metal parts – and we have them both. Our customers procure not only the machine and the laser from a single source but, in addition to extensive service support, intensive technology and applications consulting, too. No matter whether you are dealing with injection nozzles, turbine blades, tools or even medical implants, with our broad range of technology we are offering the best solution for virtually every application.”

These developments result from the company’s joint venture with Italy’s largest laser system maker, Sisma, while Trumpf has established a new division at its headquarters site in Ditzingen, which is north-west of Stuttgart, in the Baden-Württemberg region.

Concludes Leibinger: “The introduction of these new 3D printers is an essential first step, since additive manufacturing will not only supplement production techniques in the future, but will also exert a formative influence on them. We will be offering rugged and highly productive machinery with which small and medium-sized parts incorporating complex structures can be manufactured.”