At the event, a DNM 400 II machining centre (travels of 762 by 435 by 510 mm in X, Y and Z) was demonstrated equipped with Siemens 828D control, a brand that is popular among aerospace suppliers, Mills says. Previously, the Leamington-based firm offered machines with only Fanuc or Heidenhain controls.

Technical director Tony Dale says that with the change Mills is extending into a new market: “What we’re not trying to do is take the person who is happy with Fanuc and give them a Siemens. We want that Fanuc sale and want to take a sale from someone who would have bought a Siemens machine. That increases our market share.”

He says that as of early November the company has sold six units, all milling machines, equipped with the new control. Its first lathe with a Siemens control, a Lynx 220B, has now been ordered but will not arrive until 2016.

This change comes in a dynamic time for the dealer. “Only three or four years ago people considered Mills as a turning company. But we sell as many machining centres as lathes now, and horizontals too,” Dale says.

In terms of current market conditions, he reports that lathes under 12 in chuck are selling well, as well as the DNM 350 5AX machine that offers 5-axis operations thanks to a removable Nikken rotary table. On the other hand, enquiries for larger oil country-type lathes have gone quiet, given the slowdown in the oil and gas market that has cut across the industry.

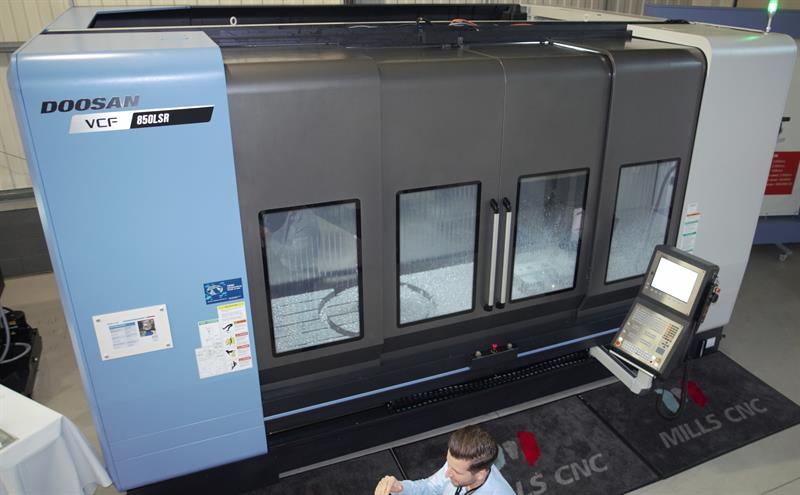

The largest – and newest – machine on show was the 5-axis VCF 850 machining centre, shown with 3 m bed and swivelling B-axis head (+/- 110°); travels are 3,000 by 850 by 800 mm in X, Y and Z. At the event, it was specced with optional integrated 800 mm turntable (a smaller unit is also available), but without centre partition that creates a separate loading area. As of early November, two orders had been taken.

At the event, Mills also highlighted its CNC training centre (there are two classrooms on site), its recently-installed CNC control demo centre, and its service and servicing operations. The latter, defined as exclusively scheduled machine maintenance, is expanding, looking to take on two additional service engineers by the end of the year, to increase its total to eight. Spread over the UK, this fleet of engineers operates in addition to the 25 Mills service engineers responding to Doosan breakdowns and other urgent work. On the day, servicing engineers’ inspections follow a detailed checksheet. They compile a list of follow-up work required; these reference parts numbers and tot up costings of parts and labour prices.