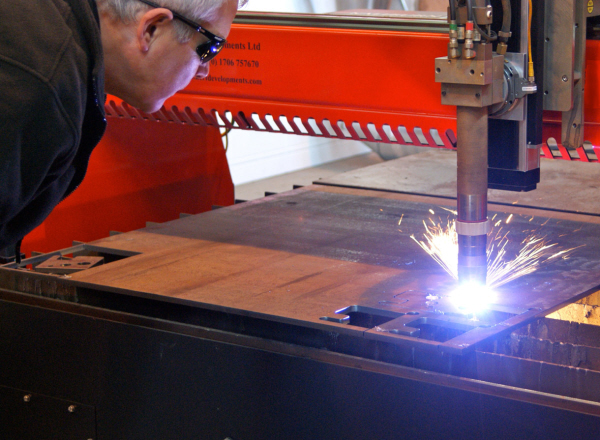

Kerf Developments has released a combined gas and plasma cutting machine called the CombiCut.

The firm says it hopes it will eliminate the need for companies to buy two machines as it brings together gas and plasma cutting in the same unit.

Kerf Developments sales director, Craig Walsh, says: "There will always be situations where Kerf does not have an ideal match on machine size and/or capability. To address this, we have developed a mid–range level of machines for oxy-fuel and plasma cutting. The CombiCut is available in a range widths and lengths to meet customers' requirements, as can be the cutting specification."

The CombiCut performs oxy-fuel and plasma cutting with minimal input from the operator and is available in three designations, the CombiCut 2000, 2500 and the 3000, each model specifying the rail span and working envelope of the 2, 2.5 and 3 m machines.

The CombiCut is a gantry type design with an independent cutting table, and is capable of piercing and cutting material from 1 mm through to 150 mm thickness.

Single or multiple cutting torches are on offer, with the option of electronic ignition and automatic torch height control.

Kerf says the rack and pinion and drive systems are fully protected from the cutting process to ensure maintenance is kept to a minimum.

Mr Walsh adds: "We believe that this new product range fills the void between quality approved second-hand equipment and our premium brand RUR and RUM high definition plasma cutting machine tools that have proven to be so popular over the years."