The Swiss-built machine joins six other Starrag-supplied machines at the Advanced Manufacturing Park – three each at the AMRC with Boeing Centre and the Nuclear AMRC.

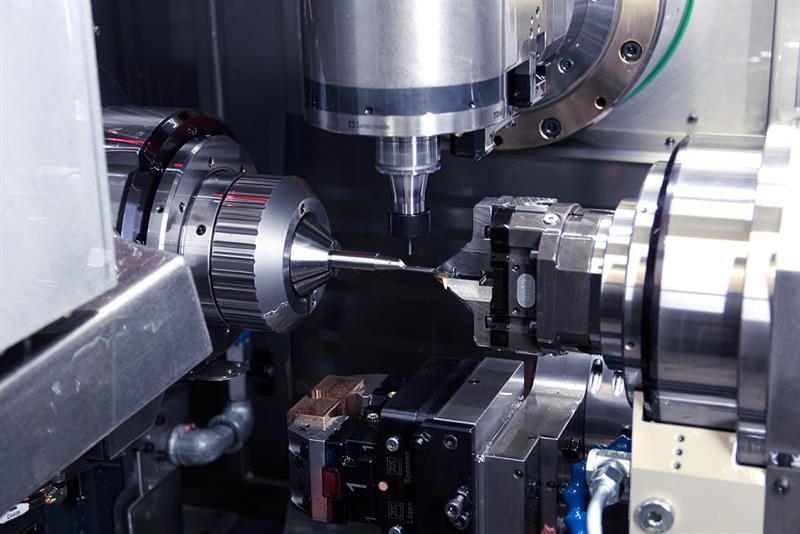

It offers a host of functions including, turning, milling, drilling, thread generation, grinding, gearcutting and hobbing. Linear drives and high level thermal stabilisation can achieve machining accuracies of 2.5 microns in the six-sided single set-up machining of even the most complex workpieces within the X, Y and Z axes capacity range of 400 mm, 200 mm and 410 mm, respectively.

Says Dr David Curtis, technical fellow at the AMRC with Boeing Centre: “The Bumotec s191 gives us opportunities to develop revolutionary new machining processes in any material and for any sector. We are now looking for projects where we can take small, complex components and develop optimised, cost-saving solutions that add value to UK industry.”

The machine will be on demonstration on 9 May, where visitors will be able to witness highly accurate solutions to industry sectors including micro-mechanics, medical, avionics and watchmaking components.