Zero-point workholding systems enable users to load/unload workpiece carriers to/from special permanent fixtures mounted on a machine tool's bed. Once a base plate has been secured to the bed and its datum location position measured ('clocked') and entered into the machine controller, it becomes the three-dimensional reference point for machining: the zero point.

Within the base plates are accurately machined holes into which studs (also called pull studs, draw bars and nipples) locate. These studs may be fixed directly to vices or screwed into components themselves. Baseplates can come with one, two, four or more stud holes pre-mounted, in grids, or in more unusual shapes such as columns or turrets, plus they can also be custom-made: "A customer had a Chiron 5-axis trunnion table, and what we were able to do is take the customer's trunnion dimensions and build a baseplate to basically be a permanent part of the machine, so it effectively replaces the trunnion table with our zero-point system," says Adrian Fitts, business development manager of WNT (UK) (0800 073 2073).

But fundamental in all this is that the hole/stud location feature ensures very little position drift: repeated position accuracy is measured as 10 microns or less in the systems examined in this article.

Fitting a workpiece into a vice that has a zero-point stud on its bottom would not necessarily be any faster than fitting it into a vice on a machine bed. The great efficiency gain of the system is that operators can attach the workpiece offline, in parallel with the machining of another part. And moving a workpiece to another machine that also has zero-point does not require any set-up as such, but rather just a series of easily accomplished quick-release connections and disconnections.

Three Roemheld Stark Speedy 2000 zero point units incorporated into a specially designed and machined flanged pillar to hold gears ranging in size from 150 mm to 700 mm in diameter. Fixture builder was PTG Workholding of Bristol, Roemheld distributor was AC Hydraulics and the customer is Joy Mining Machinery

Explains Roemheld (UK) managing director Terry O'Neill (01462 459052): "One big thing we find about the market is that speeds and feeds are increasing. The only areas where one can make savings is on changeovers. You can change the fixture over from one to another, or to a vice or a chuck, in less than a minute, and it will be within 5 micron, so you don't need to probe [to establish part position]."

Shortening the changeover time allows more time in the shift for actual machining, which increases productivity. System 3R (024 7653 8653) and Gerardi (Cutwel, 01924 869610) provide simple equations to work out the consequences of that efficiency gain. If a factory can work out an average hourly value of its spindle time, it can calculate how long payback will take: payback time (weeks) = total capital outlay divided by revenue per week, where revenue per week = extra spindle time x spindle time value per hour.

And yet another benefit is that since zero-point systems can hold multiple parts, larger arrays of zero-point baseplates can enable multiple machining operations to be carried out in one setting. Fitts of WNT recalls a real-life example of a customer that used a zero-point system to carry out four operations, over the course of which the workpiece progresses from a rough-sawn billet to machined component. Three different vice types were mounted on a single baseplate, and the machine moves from component to component through each successive operation. One component was completed in each cycle, after which it is removed, the others moved along and a blank billet inserted in the first location.

Zero-point systems need not be just for machining centres; System 3R offers manual and pneumatic systems for lathe chucks, including a vibration-dampened system that, it says, reduces cutting forces and lengthens tool life.

For location and clamping, zero-point systems rely on the special concave shape of the head of the stud. As the stud drops vertically into the fixture, one (or more) horizontal 'bolts' drive onto a taper on the stud shaft, pushing it down into the fixture and locking it, preventing the stud from pulling out. Holding forces are generally measured in the tens of kN (10 kN is slightly more than a tonne).

All the same, O'Neill of Roemheld advises checking the machining forces before designing a zero-point system, particularly for a large part, to make sure that it won't be torn out of the fixture: "If it is horizontal (cutting), and you are machining 600 mm above the table, the turning [moment] forces are high, and we would normally look at speeds and feeds and spindle power to calculate the pitch and number and size of [clamping] elements needed."

O'Neill points out that for large installations, thermal expansion is an issue: "On a three metre long aluminium plate, a one degree centigrade increase in temperature translates into 0.5 mm movement in the pitch. When you are machining to a tolerance of 0.01 mm, with that much expansion you won't get it to clamp." To deal with that – apart from building temperature-controlled areas in a factory – the Roemheld Speedy system, and many others, use three types of studs. First is the zero point stud. Only one is used, and it has no play at all. Mounted across from it is the second type, an equaliser stud, which only has play in the axis that joins it and the zero-point stud. The third type, called a floating stud, has play in both X and Y axes.

Although the purpose of all zero-point studs is the same, to grip tightly against their base plates, the means by which they achieve that goal vary. The connection actuator can be manual, or hydraulically or pneumatically-driven. In the manual systems, such as the WNT or System 3R Macro (manual version), a manual socket wrench extends or retracts a threaded bolt into a wedge on the stud shaft; other systems are self-locking on stud insertion. The hydraulic and pneumatic systems covered in this article (Leader Zero-Clamp (01827 700000), Gerardi, Schunk Vero-S (01908 611127) and System 3R Macro) require pressure to overcome springs acting on locking pistons. That means that they require fluid pressure both on unlocking, to remove the carrier plate, and on locking, to put another in. This system is failsafe; in the event of a compressor failure the zero-point system remains connected.

Another Roemheld model, Speedy Hydratec, has proved popular in automotive applications (for very heavy use), states O'Neill: "The benefit of the hydraulic unit is that users get lift. What they find is that if they have a heavy fixture, they have to crane it in; with this system, it lifts the fixture 2-3 mm, and takes it out of the location, making it easier to crane out."

Fitts of WNT (UK) emphasises the benefits of the manual system: its cost, something like 40% less than other products; the thinness of base plates allows greater working volume; and its simplicity. "You don't have to be concerned with hydraulics; you can build up a workholding system simply. And our products are available from stock; customers can look at the catalogue, or sit down with one of our [sales] guys, and build up a small kit from the catalogue to get running. Two weeks later, when they need to do another job, they already have the equipment they need," he says. Vice jaws are also interchangeable, further aiding system flexibility.

60-pallet spiral gravity-fed Eco Tower automation system from Thame Workholding using zero point for workpiece loading and unloading

HEADING INTO AUTOMATION

- Zero-point systems lend themselves to robot loading and unloading. For example, Thame Workholding (01844 208050) offers the Lang range of automated systems, designed to be easy to install and operate. Just two M-codes are required to interface between the Lang system and the machine tool's CNC. A variety of sizes of machine, from 10 and 20 to 60 pallets, can be integrated. The handling unit operates at low speed, using shopfloor compressed air, so the system does not require the complex interlocked guarding that would be necessary for an industrial robot. The robot gripper actuates the zero-point clamping system inside the machine tool via a pneumatic interface. Even with the automation installed, manual operation of the machine is still possible. Thame has two of the tower systems installed in its own workshop, supporting its 24 hour 5-axis machining facility.

- Elsewhere, Hampshire-based specialist machining subcontractor Di-Spark automated its spark erosion cell by combining a System 3R WorkPartner robot with its AgieCharmilles Form 2000 HP EDM machine to increase its production efficiency. The WorkPartner incorporates 10 positions for 320 by 320 mm zero-point pallets and up to 90 positions for electrodes. This allows setting-up when the machine is running and supports continuous lights-out operation. Working problem-free since it was installed several years ago, the automated cell was instrumental in Di-Spark securing a major aerospace components contract.

RECENT AND RELATED PRODUCTS

- Schunk's Vero-S SPG 40 clamping stud has a flexible cone around its axis to offer play-free positioning of less than 2 micron. It allows for thermal changes without moving the zero point. The stainless steel studs support a holding force of from 35 to 50 kN. Users of Vero-S NSE plus zero-point systems can swap their existing studs with the new model.

- A recently-developed Gerardi (Cutwel, 01924 869610) self-centring or eccentric vice that can be used with Gerardi zero-point systems has a compact design to allow simultaneous 5-axis machining in one single set up, without requiring special fixtures or workholding systems. The hardened (60 HRc) vice features jaws with adjustment steps of 2 mm are interchangeable. Jaw inserts include stepped, gripper, soft machinable, hard, prismatic and serrated jaws.

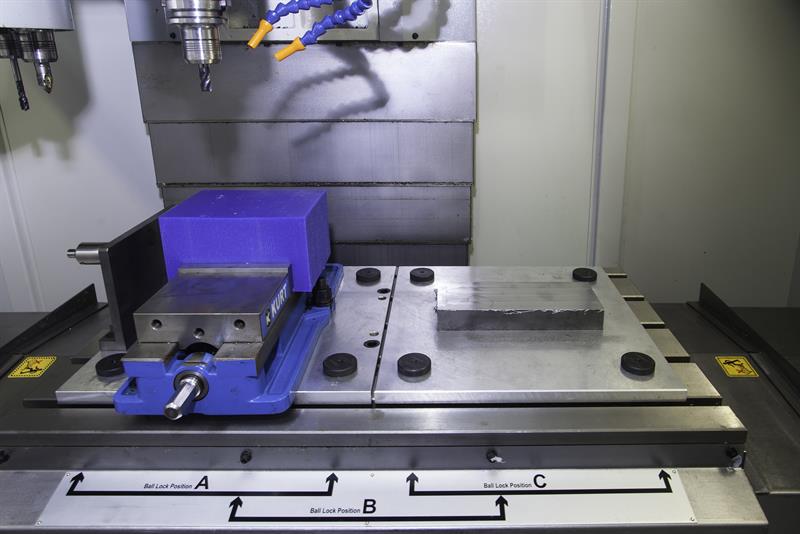

- An alternative to installing a zero-point workholding system on a virgin machine is the Prototrak LPM from XYZ (01823 674 200). Standing for Lean Production Machine, the model incorporates three datum holes positioned to a tolerance of 2 micron on its 900 by 500 mm machine table. Fixture plates are then located and clamped in position, using the Jergens Ball Lock system that features a clamping force of 1,000 kg from the turn of an Allen key. When programming the part, all the user has to do is identify which datum point – A, B or C – is being used and where the datum point on the carrier plate is for machining to start. The machine uses the simplified ProtoTRAK conversational control system and has axis travels of 785 mm by 470 mm by 530 mm in X, Y and Z, respectively.