While in an ideal world every machinist would be up to speed on cutting tool knowledge, in the real world there are many reasons why their tooling knowledge may have a few gaps.

Training need not always require time off of work. Sandvik Coromant’s web-based metalcutting e-learning programme, which is free, offers a multimedia introduction to the topic that can be employed in isolation of a machine or trainer (video: http://is.gd/iwejap). It works alongside the bulk of the company’s training, offered face-to-face on-site or at its Production Centers worldwide (Halesowen in the UK), although it does also provide other e-learning materials for channel partners and distributors.

Sandvik Coromant says: “For us it’s a way to encourage learning and position ourselves as the go-to source for metalcutting knowledge.” Since the course launched in 2013, 25,000 people have signed up; now the company is in the process of updating both the course and the handbook.

As a free service, the course can’t be faulted. One suggestion to extend it would be the addition of a moderated chatroom/bulletin board to allow the student/customer to ask questions or otherwise interact with the expert/vendor.

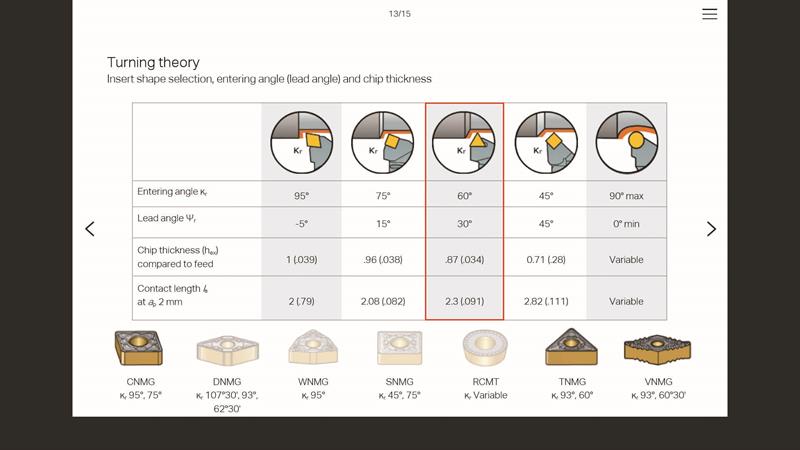

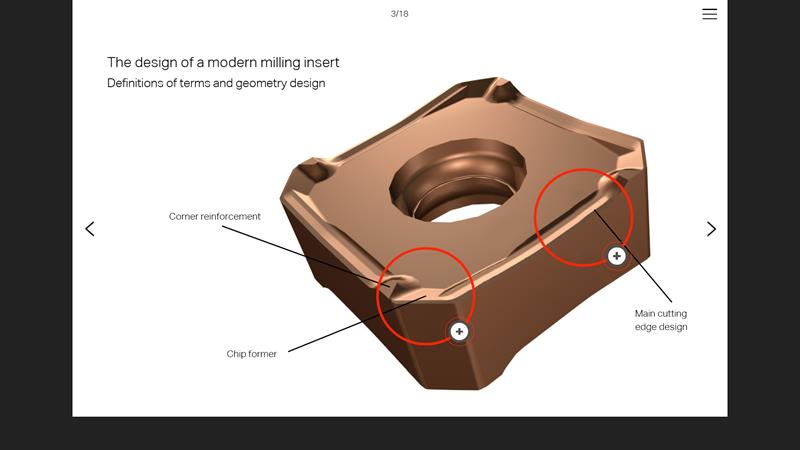

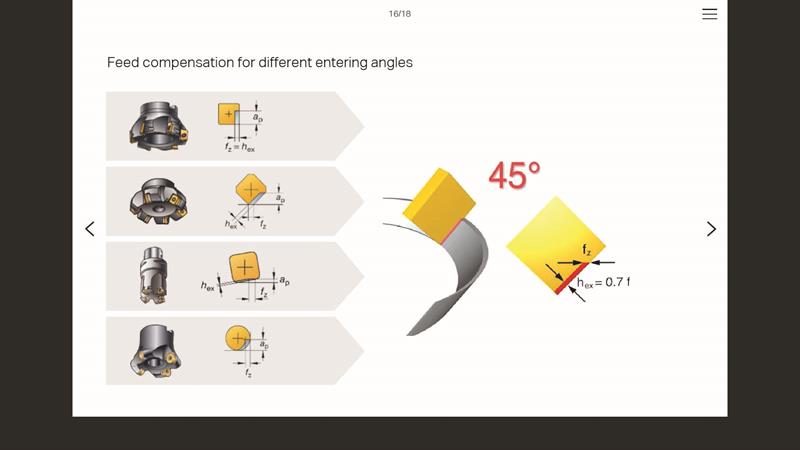

The meat of the material is covered in a sequence of slides containing a few dynamic or pop-up elements. Based on the company’s full-colour Metalcutting Technology Training Handbook (also free, via http://is.gd/mozopi), the online content is easier to digest, but briefer, than the 360-page manual. The course shares the look and production values of the handbook; in particular its good-looking and high quality graphics. Animated video demonstrations of metalcutting processes are a highlight.

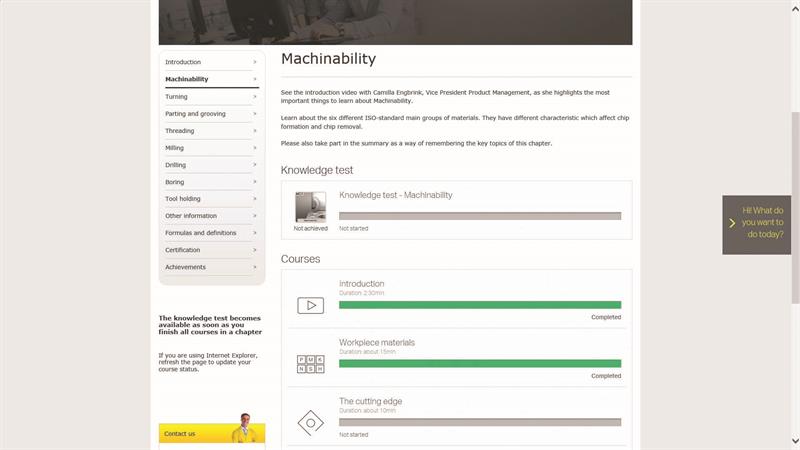

Although Sandvik Coromant supplies tooling, and that’s the lens through which machining is seen, the course remit is broader. It covers materials and cutting tools (under ‘machineability’); turning; parting and grooving; threading; milling; drilling; boring; and toolholding. Both cutting theory and its practical applications are covered. Sandvik Coromant says that the e-learning course, which it calls a “first step into the world of metalcutting”, will enable students to answer questions such as: “How do I calculate cutting speeds?” “How can I increase tool life?” and “What causes this type of insert wear?”

The system tracks students’ progress, section by section, recording what sessions and elements have been started and completed. Users are required to create a (free) Sandvik Coromant account to access the course, which lives on its website, so an internet connection is required (it works well with iPad tablets, incidentally). Content is well organised by topic, and broken down into small chunks (of less than 20 minutes). Each section offers a mini-test for a badge. Those who complete every section (said to take 15 hours) and successfully complete the final exam win a certificate.

Although the course does contain a few equations (with both metric and American units), a good spatial sense to interpret the diagrams is as important as mathematical ability. Neither task should be challenging for an apprentice. On the other hand, this course is intended for students committed to the material: it doesn’t teach a correct technical attitude, nor evangelise about the potential of a career in production engineering.

This article was published in the March 2017 issue of Machinery magazine.