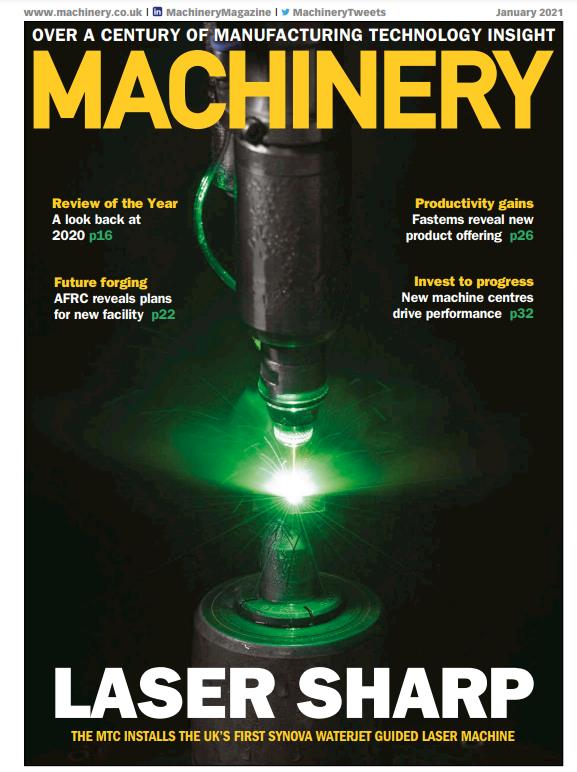

The state-of-the-art five-axis system allows engineers to cut, drill or machine complex shapes without the drawbacks associated with traditional laser machining, such as heat build-up or tapers. The Synova machine can be used on a range of materials including ceramics, hard to machine alloys and composites among others.

Speaking to Machinery, Bethan Smith, technology manager at the MTC, says the high-powered waterjet guided laser allows the centre to develop and use the latest technology to support industries across the UK with their manufacturing challenges.

Smith explains that the investment is a key part of the Coventry-based MTC’s strategy moving forward: “We see laser processing as a key manufacturing technology for the UK, and as such this is one of the MTCs key strategic areas going forwards. To back this up we have made quite a few investments in this area of technology over the last few years.”

The MTC already operates a Amphos (now owned by Trumpf) 300W Picosecond laser that it uses for high precision machining. The machine is also currently the only one in the UK and ties into the MTCs laser machining capability, similar to the Synova machine.

“We are really pushing for the use of laser processing and trying to support its uptake in the UK, which has been slower than in other countries around the world, to support this we are working with all the suppliers in the sector,” says Smith. “We now have a lot of capability and the Synova slots in there to support the others that we operate giving us a wide range of laser offerings for manufacturing companies to trial and assess on-site.

“For example, we will be helping to develop production solutions for the machining of lightweight, high performance, hard to machine materials that will be crucial in helping manufacturing businesses hit the UK’s upcoming net zero targets.”