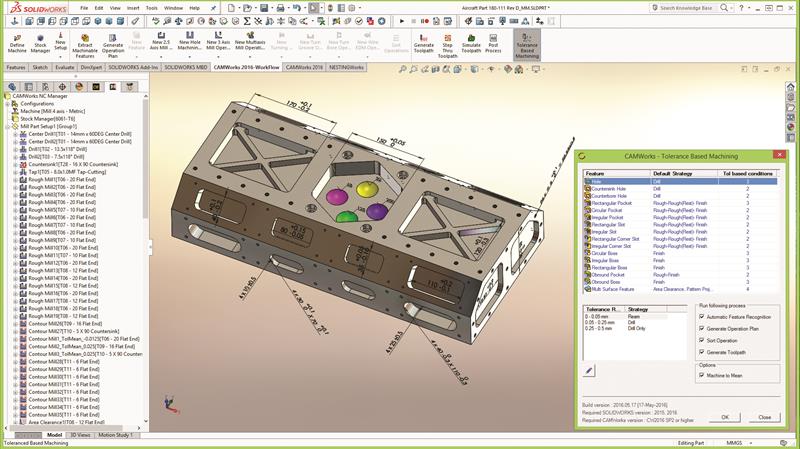

One of the more dramatic product claims heard recently comes from Geometrics, developers of CAMWorks 2016 (New Technology CADCAM; 01844 295 235), which states that CAMWorks automates the machine tool programming process. Starting from an annotated Solidworks 3D part model, it will identify features and generate a toolpath, choosing speeds, feeds and tools. All on its own.

This solution rests on five different technology innovations, each of which accomplishes a small part of the whole. Some are brand new; some not.

First is a development in Solidworks 3D CAD, with which CAMWorks can link, as the latter’s developer is a certified gold partner of Solidworks (also available from New Technology CADCAM). Geometric dimensioning and tolerancing (GD&T) information that might normally be found on a 2D drawing has, for some time, been able to be added into a Solidworks 3D model, using the standard DimXPert functionality. Earlier this year, CAMWorks 2016 was augmented to be able to extract those data, called MBD or ‘model-based definitions’.

The second element, also new, helps to overcome a niggly problem in this process that bridges a gap between design and manufacturing engineering. It automatically translates the different upper and lower tolerances specified by designers for features, such as press fits, into mean figures suitable for machining. Says CAMWorks’ Marc Bissel: “The combination of Solidworks and CAMWorks allows the design and manufacturing models to become one and the same.”

The third element involves an automated step that is not new. During the automatic feature recognition process, CAMWorks finds all of the machineable features in the annotated 3D model; it can apparently recognise 20 different types of features.

CAMWorks 2016 reads GD&T data on a SolidWorks 3D model and selects cutting paths based on features’ pre-set tolerance ranges. Video: https://is.gd/sehoci

Fourth is another existing CAMWorks element that provides automation – ‘knowledge-based machining’. This employs a technology database that aims to capture programming practices. It applies pre-set parameters to process the features found in the model in the previous step to create machining operations – including tools, speeds and feeds.

Finally, a new CAMWorks element called ‘tolerance-based machining’ increases the sophistication of the process. It recognises that different features may have different tolerances, so achieving closer tolerances requires different tools, feeds and speeds to those employed to cut a feature having wider tolerances. This element provides a way to assign different tolerance ranges to different features, and also to specify which machining strategies are to be used for each tolerance range. Thanks to this element, the cutting toolpaths that are generated automatically can more faithfully reflect the need of a complex part.

The end result of all of this automation is a net speed gain. Says Jim Foster, Geometric vice president of channel marketing and sales: “CAMWorks with tolerance-based machining will save 70% to 90% over the typical times involved when using traditional CNC software to prepare parts and assemblies for machining.”

Also expressing a disruptive idea – that also promises time reductions – is manufacturing software developer NCSimul (www.ncsimul.com)

NCSimul 4CAM is a CAM system that can: take input in numerous formats, even mixing and matching them; allow users to create programs by reusing code from existing programs via copy and paste; add new code by performing native CNC programming; and convert existing programs for use on alternative machines. It achieves all this without the need for a post-processor.

First, 4CAM accepts 3D models from Catia, Siemens NX, Creo, Topsolid CAM and MasterCAM, or CAM files in APT or CL-data format, or G-code compatible with Fanuc, Siemens, Heidenhain or NUM machine controls. Any of those can be modified or reused during the process of a partial or total toolpath replacement. The output G-code sees changes capitalised for tracking purposes, and changes are logged. Connections between machining sequences are said to be automatically optimised.

In addition, an integrated CNC processor natively processes the CNC program, based on machine parameters and NC controller logic. It can also simulate the process, showing part stock status at any point.

Third, NCSimul 4CAM enables users to take a CAM file originally designed for one machine and adapt it to another in one quick step, without using a separate post-processor or separate simulated prove-out step. A video (https://is.gd/nedeju) demonstrates an operator moving a CAM file from one machine to another, checking to see which one is appropriate for the job by running a quick G-code simulation to reveal clashes or collisions.

The company says: “NCSimul 4CAM, a complement to your existing CAM, will significantly reduce your programming time.”

The package is part of a family of production engineering-related software.

Another software suite that promises to “allow the programmer to create toolpaths for the part without much consideration given to machine kinematics” is ICAM’s Adaptive Post-Processing suite (Desktop Engineering, 01993 883555). That software, augmented by three toolpath optimisation modules released last year called SmartPack, is said also to streamline the task of transferring a program to a second machine tool. Together, they automatically update an NC program, based on the findings of a post-processing simulation (video: https://is.gd/dadoya).

Here is ICAM’s view of the traditional process: a CAM system produces an APT file that is translated into G-code by a post-processor; the G-code is verified by a machine tool simulator and an error report is produced; this report is analysed, interpreted and acted upon by the programmer modifying the CAM file. This process may be repeated several times.

ICAM says its system short-circuits this, generating time savings of 25-35%. Its system processes the APT file, simulates the G-code and optimises the program in a single step.

To do that, the Adaptive Post-Processing software suite consists of a post-processor development engine – it supports at least 13 CAM software packages – and a machine simulator that incorporates a G-code NC program emulator. The latter intelligently updates the former; for example, machine collisions and over-travels are automatically detected and fixed in post. Whenever a collision is forseen, the post will automatically reposition the tool into an alternative arrangement to avoid it.

To optimise cycle time, during this process SmartPack modules are employed to remove unnecessary spindle movements. Each of the three modules focuses on a different aspect. SmartPath takes into consideration the state of in-process stock, the fixtures and machine components to avoid extra moves. SmartCut aims to speed up transitions between cuts. It checks the NC program against a simulation of material removal in the designed part; where it finds instances of air cutting it changes the motions to high feed positional movements. SmartFeed uses another material removal simulation to recalculate programmed feedrates, depending on machine tool capabilities, reference cuts and degree of stock engagement.

Of the software, ICAM says: “Manufacturers can now reduce NC programming and machine cycle times – automatically”.

While software developers may never be able to remove a skilled programmer completely from the process of transposing CAD files into CNC machine tool language, there are market movements in that direction, based on the evidence of these products, anyway.