With the introduction, Kellenberger sees the high performance, economical grinder segment in the its portfolio being completely overhauled to make it fit for future. The machine is offered in the UK through Jones & Shipman Hardinge.

In terms of functionality, the new 200 mm centre height 100 platform with either with 600 or 1,000 mm between centres far exceeds the capabilities of many existing grinding machines, it is claimed.

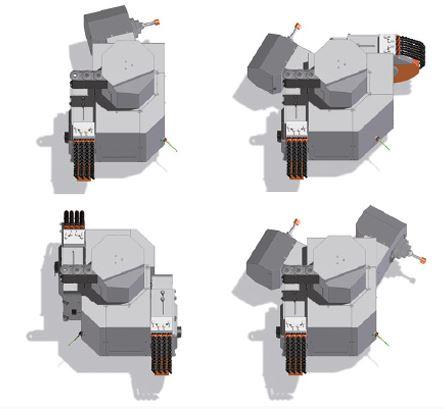

Various grinding spindle layouts are offered

Because of its modular configuration, assembly of 100 series machines is simplified, making it possible to optimise manufacturing costs for the machine and ensure an excellent price/performance ratio for the purchaser. Numerous ‘standard’ options can put the customer’s finishing touches on each individual machine.

The user-friendly and ergonomic design of the Kellenberger 100 machines also features a new, simple operator guidance system with an intuitive touch-screen panel. The machines are equipped with the latest Fanuc 31i CNC controls with 19-in touchscreen and a newly designed cycle programming or workpiece-related graphic programming is an option.

Other features include an innovative, collision-free, compact tandem wheelhead, the ability to fit larger grinding wheel diameters for internal grinding and a choice of 10 wheelhead variations for optimum layout of the machine.

There is also increased drive power at the grinding wheel, a newly designed Z guideway and a C-axis with direct drive for high precision, non-circular grinding.

Finally, there is a service-friendly design permitting faster maintenance and service operations, with good access to components requiring frequent attention.