The light cutting shoulder mill is one of the most common tools found in machining centres’ tool magazines, says Sandvik Coromant (www.sandvik.coromant.com/uk). This is because, apart from shoulder milling being one of the most prevalent machining operations, the cutters are versatile enough to be used for face milling, slot milling, ramping and more. Sandvik Coromant’s CoroMill 390 family is a state-of-the-art family of square shoulder milling cutters, but has now been extended with the addition of the smaller 07 insert size end-milling cutter style.

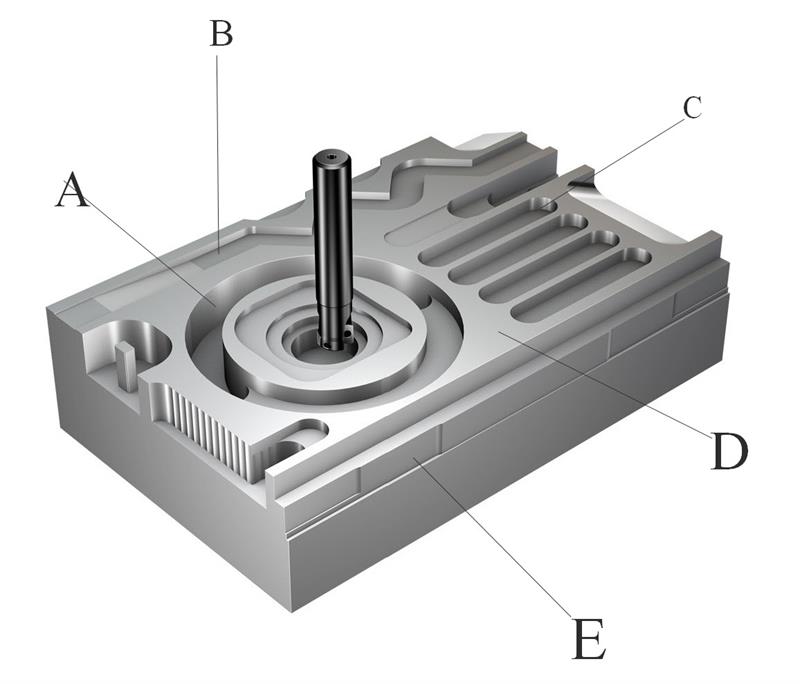

The versatile cutter can undertake:

The versatile cutter can undertake:

A - Pocket milling requires efficient and secure opening of cavities. Strong insert face geometry supports helical interpolation and linear ramping to create holes from a solid workpiece, with inserts withstanding consequent stress, giving a low-vibration process with even tool life

B - Slot milling requires good chip evacuation and vibration suppression. Insert geometries designed for favourable chip formation and chip evacuation, plus differential pitching deliver a low-vibration milling process

C - Key slot milling requires accurate slot dimensions to close tolerances. CoroMill 390 includes cutters with size 07 inserts having a tool diameter 0.3 mm smaller than the slot width, leaving stock for subsequent finishing

D - Face milling requires a high removal rate and good surface finish. CoroMill 390 inserts support ambitious cutting parameters, with –L geometries delivering low cutting forces, high quality surface finish and close tolerance machining

E - Shoulder milling requires precise contours without steps at the differing depth levels. Close-tolerance inserts plus exact and secure insert positioning combine with a smooth cutting action that limits radial cutting forces, delivering minimal bending and, therefore, good wall perpendicularity

The existing CoroMill 390 system includes three larger insert sizes, 11, 17, 18, with these taking in end-mills, face-mills and long-edge milling cutters able to cut at depths up to 15.7 mm. The size 07 insert end-mill boasts diameters of from 9.7-25.0 mm and supports axial cutting depths of up to 5.8 mm. In the 07 size range, cutter bodies can incorporate two, three, four, five or seven inserts, with diameter ranges crossing over (see box item, below).

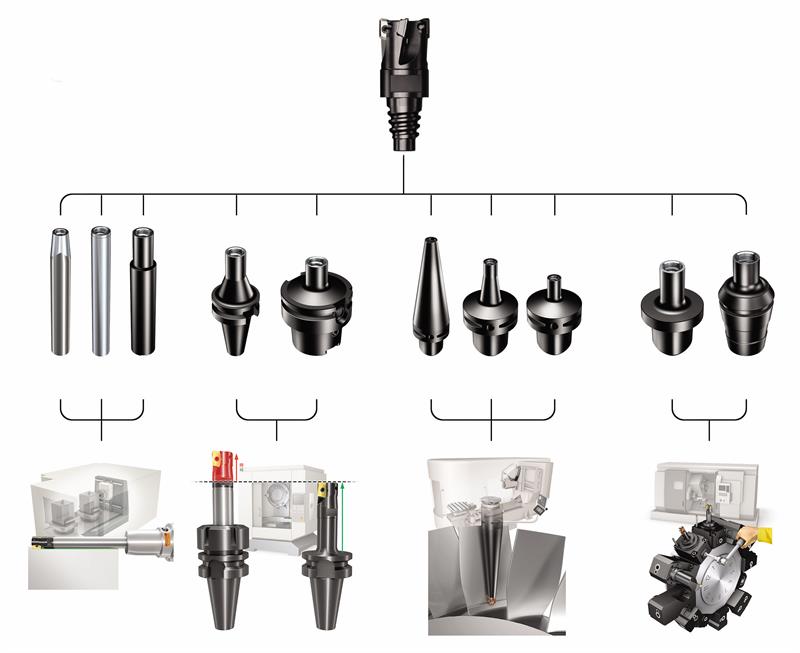

Cutter body styles available take in an exchangeable head (EH) version, which can be used with a variety of back ends covering short- to long-reach requirements (see image, page 13), and cylindrical shank versions that can be used with Sandvik Coromant’s hydraulic chuck range, CoroChuck 930. These chucks are available in heavy duty, slender and pencil versions that have varying shank diameters. Both EH and cylindrical shank versions are available across the full diameter range.

Specifically for multi-tasking machines, undersized shanks are offered in different lengths and materials for the CoroMill 390 family, providing stability and clearance when milling at long overhangs. And for lathe turret driven tool positions, a short tool assembly comprising only the adaptor and cutter keeps tool length low.

The CoroMill 390 07 EH range – a wide range of back ends is offered

A new steel milling insert grade GC1130 launched at the same time as the 07 size insert CoroMill 390 and employing Zertivo PVD coating technology, delivers longer tool life and more secure machining through high edge integrity – four inserts are available in this grade (ground and pressed styles in each of two geometries). In total, there are 23 inserts available for the 07 size system (in both metric and imperial versions) across eight insert grades, two geometries and two radii. There are 594 inserts across 22 insert grades, 10 geometries and 14 radii for the whole CoroMill 390 range.

VERSATILITY THE TARGET

The objective with the new product was the creation of an extremely versatile cutter for a wide range of operations and materials. Trouble-free, reliable milling performance, as well as easy-to-use insert clamping to increase process security were targets.

A perceived downside of versatile tools is that they may be good at many things but not great at specific operations. With this in mind, Sandvik Coromant set about refining the new CoroMill 390 end-mills’ performance to negate that potential criticism.

Supporting that are a number of technical features. The end-mill cutter bodies are produced in a new material with increased heat resistance, while parts of the range have been optimised with differential pitch for applications that are particularly prone to vibration (generally three-, five- and seven-insert tools). A new torque key is delivered with each cutter, with its built-in spring functionality making it easy to mount inserts at the correct clamping force and so deliver reliable and consistent tool life. Maintaining this process security theme, internal coolant delivery is a feature of all the tools; ideal for slots and for machining of materials where elevated temperatures are undesirable.

Process security also featured highly on the agenda when developing CoroMill 390 inserts. With this in mind, the light cutting geometries (-L) and high performance insert grades of this cutter concept are designed to give secure milling in all material groups. For steel milling, the new first choice insert grade is GC1130, which, says Sandvik Coromant, offers a new level of process security, thanks to long and predictable tool life with a clean and intact edge.

With all this, CoroMill 390 with size 07 inserts provides reliable cutting. For example, the efficient and secure opening of cavities to support pocket milling typically requires helical interpolation and linear ramping when machining from solid.

This task, says Sandvik Coromant, requires a strong insert face geometry (-M) to withstand the stress caused by steep ramping or demanding interpolation and so allow a low-vibration process with even tool life.

SMOOTH CUTTING ACTION

In shoulder milling operations, close-tolerance inserts and exact insert positioning help produce shoulders without steps. The smooth cutting action of CoroMill 390 limits radial cutting forces, resulting in machining with minimal bending and, therefore, good wall perpendicularity (-L geometry supports this).

Slot milling offers a different set of challenges, these typically centred on chip evacuation and vibration. Indeed, these issues are exacerbated when milling with large engagements, as vibration often accelerates tool wear. A light cutting geometry (-L) in combination with a cutter featuring optimised differential insert pitching can take care of this issue and so deliver a low vibration milling process.

In a customer example involving slot milling, productivity was limited as the customer’s two-insert end-mill could only manage a cutting depth of 2 mm. Having switched to a 12 mm diameter CoroMill 390 cutter with three size 07 inserts of ISO grade P/geometry -M and boasting differential pitching, the cutting depth was increased to 3 mm. Furthermore, cutting speed was increased by 33%, and feed by 50%. The upshot was a productivity gain of 225%. As a bonus, burr formation caused by the previous tool was eradicated.

For key slot milling specifically, the CoroMill 390 cutter with size 07 inserts is available with a tool diameter 0.3 mm smaller than the slot width (XX.7 mm diameter tools, box, p12) such that a suitable amount of stock is left for the subsequent finishing operation.

When it comes to face milling, the goal for machine shops is usually high metal removal rates with good surface finish – an ambitious combination not easy to achieve. For this reason Sandvik Coromant has designed geometries (-L) for milling with low cutting forces that prove ideal for facing surfaces that demand a shiny finish and close tolerances.

The CoroMill 390 size 07 system’s smaller inserts allow for a higher cutting edge density, offering superior output in many different milling operations. And in combination with the new steel milling grade GC1130, the tool delivers optimised productivity, the company adds.

Main article ends

CoroMill 390 07 – Sizes, grades, geometries

Sizes:

Two-insert cutters – 9.7, 10, 11.7, 12, 13.7 mm

Three-insert cutters – 11.7, 12, 13.7, 14, 15.7, 16, 18 mm

Four-insert cutters – 16, 20 mm

Five-insert – 20, 25 mm

Seven-insert – 25 mm

ISO application areas: P (steel), M (stainless steel) K (cast iron), S (heat-resistant super-alloys) and N (hardened materials) are covered

Grades: 1020, 1040, GC1130, 3330, 4230, 4240, S30T, H13A

Geometries: -L (light machining) and -M (for more aduous duties) geometries are variously applied across the insert grades.

Radii: 0.2 and 0.4 mm

First published in Machinery's 'Tooling & workholding supplement' in May 2016