A fifth-generation family business, Keller Technology serves customers around the world. In addition to its manufacturing facility near Buffalo, New York, USA, it operates an assembly plant in Charlotte, North Carolina, as well as affiliates in Seoul, South Korea. The company traces its roots back to 1918, as a general job shop servicing customers in the local area. The next four decades saw the company evolve to provide machine building services to customers throughout the United States. Today, Keller Technology specialises in equipment used to manufacture semi-conductors, medical devices, food products, commercial and industrial products, as well as equipment to support research at universities and national laboratories.

The company’s workload is typically made up of high value jobs that often involve low quantity production of parts having complex geometries that allow no room for error or any second chances. For jobs like this, proving out machining processes before the cutting tool meets the metal is critical, although that can’t work counter to timely deliveries. Steve Ziff, CADCAM manufacturing engineer, says one particular system is critical to meeting both of these potentially conflicting goals: VERICUT CNC simulation software from CGTech (01273 773538). Since installation a few years ago, the software has eliminated the need for time-consuming manual prove-outs, improved shopfloor confidence and enabled faster workpiece set-ups.

HEAVYWEIGHT CHALLENGE

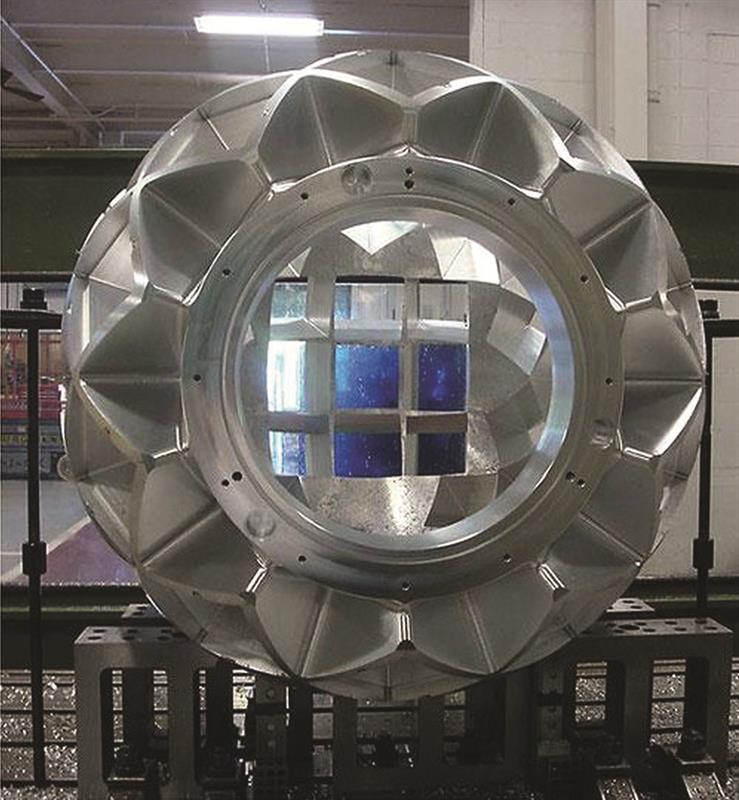

A recent project that has benefitted from the application of the advanced simulation software is a large spherical component for a high resolution diffractometer used by the US Department of Energy. It started as a forged piece of aluminium measuring just over 1 m in diameter and weighing more than 1,360 kg. Machined on a Parpas SL 100 5-axis milling machine, the part required the removal of more than one tonne of material to bring it to its final weight of 277 kg. Like most of Keller Technology’s work, the part was a one-off item requiring high precision, custom tooling and relatively protracted machining routines, and it had to be manufactured right first time. Welding to fix any gouges was not permitted.

Prior to implementing VERICUT, the company would most likely have proven out the part program manually by running the machine through a mock cycle on the shopfloor. Steve Ziff says: “That alone would have wasted a great deal of valuable machining time, not to mention the hours shopfloor personnel would have spent properly orienting the part.”

Weighing in at over a tonne, there's no easy supply of more raw material, should things go wrong

Cutter clearance was a particular concern, because the forged aluminium sphere and its custom fixture could barely fit within the machine’s working envelope. This problem was exacerbated by the fact that the 51 square, tapered pockets located throughout the part surface measure as deep as 355 mm in some cases, necessitating cutting tools protruding a long way out of the spindle nose.

Still, a manual prove-out would have been more reliable than the most readily available alternative: the simulation capability embedded in the company’s CAM system. “The problem,” explains Steve Ziff, “is that the CAM-integrated verification capability is limited to checking only the internal CAM file. As a result, the system evaluates only the cutting tool’s interaction with the part without accounting for other factors that affect the process. In the real world, you have a lot more things to worry about, such as doors, clamps, angle plates, how the part fits on the table, and there was no representation of the full machining environment.”

VERICUT provides just such a representation, with user-defined virtual models of all equipment involved in the production process. Upon installation of the software, the company’s programmers input information for every machine on the shopfloor, including not only axis travels and other physical dimensions, but also feeds, speeds, horsepower and other attributes. Access to that sort of information enables the system to issue a warning in the event of any discrepancies between the program and the actual equipment capabilities, such as when a CAM file calls for 10,000 rpm on a machine only capable of 3,000 rpm.

Custom tooling, fixtures and part models are passed into the simulation software via an interface with the CAM system. The resulting virtual environment provides the context for simulations that run from the same post-processed G-code that drives the machine tool.

This is in contrast to CAM-integrated simulation that is limited to only the internal CAM file and so ensures a more comprehensive rendering of how the process will proceed on the shopfloor.

The fully machined diffractometer part. CGTech VERICUT made sure all was well

SEEING MORE THAN CAM CAN

“What VERICUT does is put the code in the driver’s seat,” Steve Ziff says. To explain, he cites the example of a tool change. The CAM simulation module depicted the machining routine proceeding seamlessly with the new tool instead of the old. Perfectly fine for determining the viability of the toolpath itself. However, what is lost are the spindle’s moves away from the workpiece, toward the machine’s carousel for the tool swap and back again to the point of the cut, all while avoiding any potential collisions. Simulation based on the actual G-code accounts for such moves, which are particularly important for large parts like the diffractometer component that might experience clearance issues.

Comprehensive simulation within a realistic rendering of the machining environment saved significant time and money during the planning phases of this project. As Steve Ziff highlights: “CAM-integrated verification would have had little to offer in terms of designing the part’s custom fixture, orienting it within the working envelope and determining the proper lengths for the custom tools used to machine it. Manually performing all the trial-and-error tests required for this process would have been both time- and cost-prohibitive. With VERICUT, the labour involved amounted only to mouse clicks. It’s easy for us here in programming to, say, move the fixture 250 mm and see what happens. Doing that out on the machine would take a very long time.”

While difficult even by Keller Technology’s standards, the diffractometer component job provides an example of how VERICUT provides the confidence needed to machine high value parts, without the time demanded for manual prove-outs. “With some large forgings approaching $250,000, we do not have the luxury of just throwing another piece of stock on the machine after a mistake,” concludes Steve Ziff.