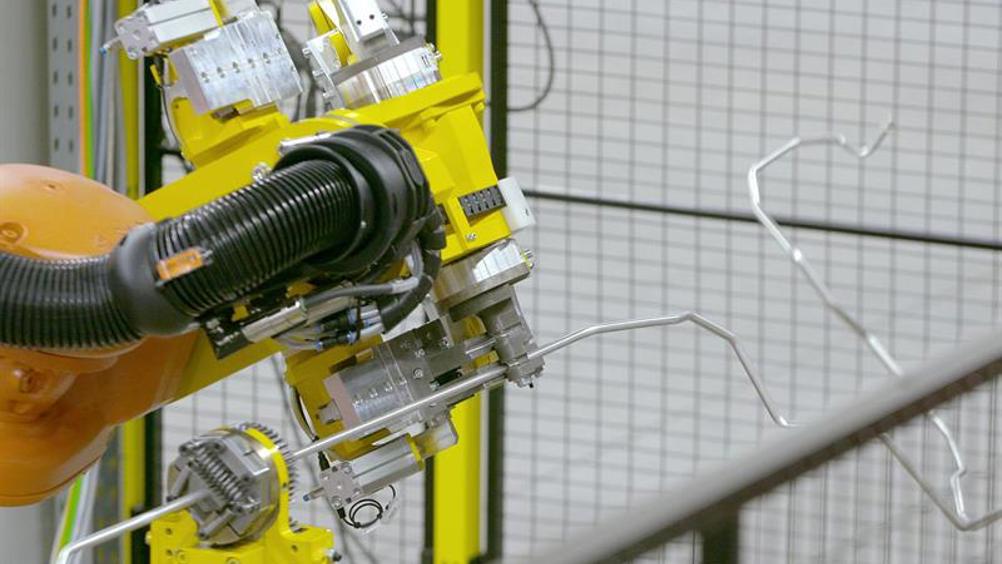

The process starts by inserting a bundle of tubes into a feeder that are then orientated individually by symmetrical rotation, according to the positioning of the flanges. Each tube is then picked up by one of two system robots, which then transfers it to a moveable spanning device with an appropriately high retaining system designed for longer tubing. The spanning device allows the robots to process the tubes on one or two sides in parallel.

Transfluid develops robot-assisted tube bending system

The production of tube lines with a length of 1,500 mm and diameters as small as 18 mm for braking systems, air conditioning units and similar devices represents a challenge, specifically with regard to handling. For this reason, Transfluid has developed a robotic processing system that can bend tubing in lengths of up to 4,500 mm – at rates of up to 47 bends per 140 seconds.