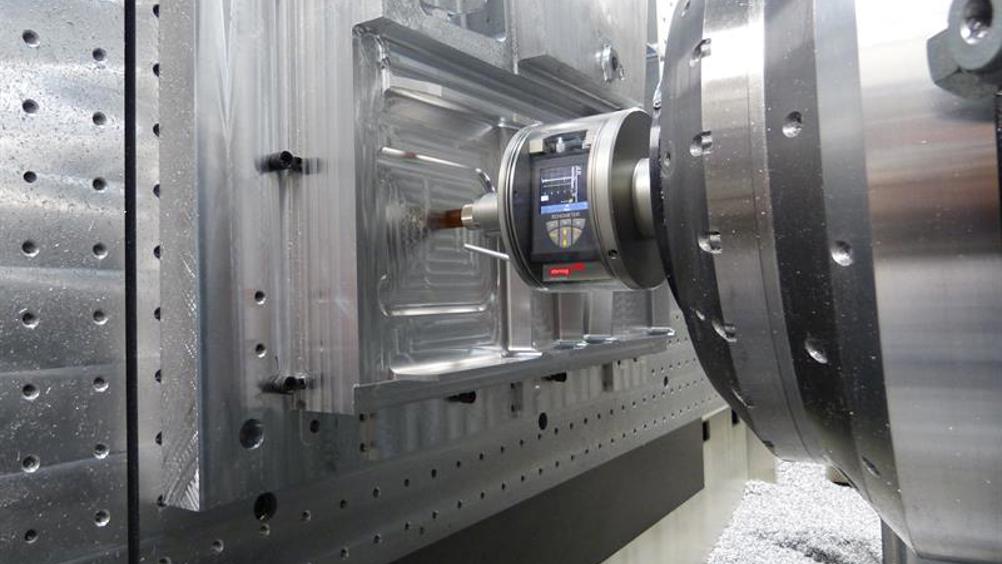

Sonic Eye can be exchanged like a standard tool from the tool magazine, with all measured data saved and available for documentation and later machining operations. The system uses radio transmission to relay measurement data to the machine’s CNC system. Data is correlated simultaneously with measuring points detailed in the control system’s NC program, while the resulting protocol of the measured thickness for each measuring point can be tabulated for export into Microsoft Excel.

Starrag’s Sonic Eye automates floor thickness measurement of aluminium parts

Starrag Group’s Sonic Eye is for the automatic, in-cycle measurement of workpiece floor thickness on Scharmann Ecospeed machining centres. The device dispenses with the measurement of floor thicknesses as a separate, off-machine process – eliminating the need to relocate workpieces, if further machining is required – therefore reducing overall lead-times.