Nikon XTH 450 for inspecting large and dense parts

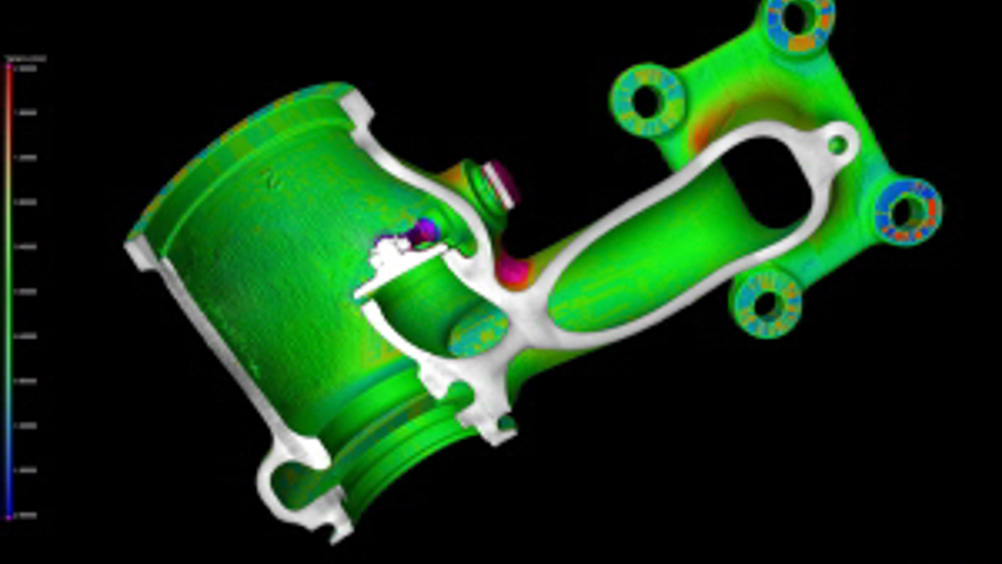

The XTH 450 CT (computed tomography) system from Nikon Metrology is said to set a new standard for measurement and non-destructive testing and inspection, especially of turbine blades and cast metal parts. At the core of the system is the in-house-designed, 450 kV micro-focus source (the only one on the market, says Nikon), providing superior resolution and accuracy compared with traditional mini-focus sources.