The line includes four machines, PJ812, J1220, J1230 and J1625 (specifications below). They provide positioning accuracy and repeatability of ±1 micron. A thermal compensation system employs sensors on the machine faceplate and inside the spindle to minimize the effects of temperature changes on part accuracy and cut temperature-generated displacement by 60%. This system also reduces Z-axis thermal growth and deflection by 30%. Cooling systems for slide way lubrication and ballscrew cores stabilise axis feed precision.

Mechanical design features that maximise machine rigidity and accuracy include hardened and ground tool steel box slideways as well as contact elements that enhance acceleration, reduce stick-slip, and allow for feed accuracy of 0.1 micron. Another proprietary engineering detail drastically improves the static rigidity of the Z-axis to more than six times that of conventional Z-axis arrangements.

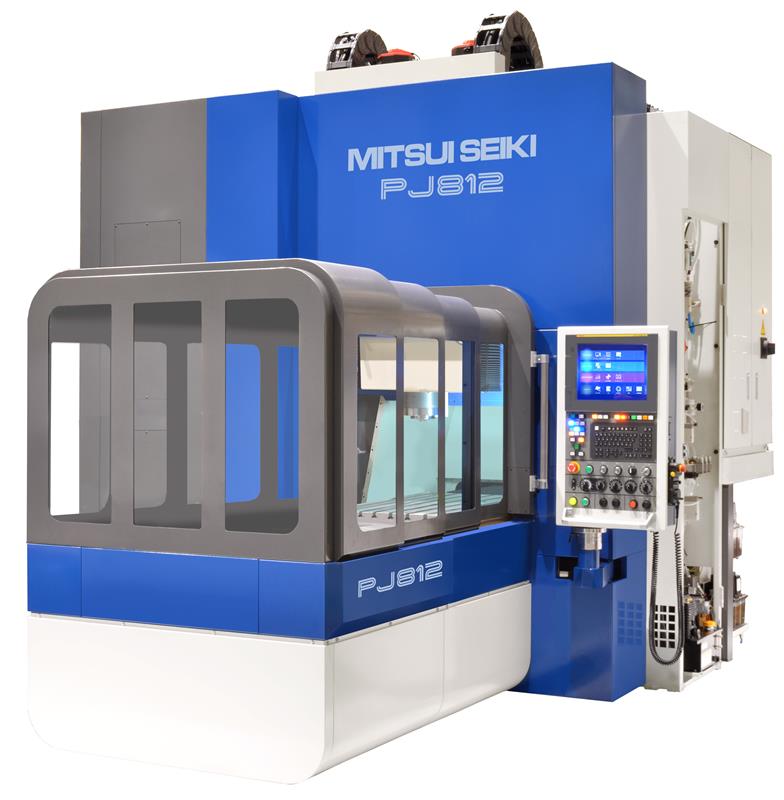

These heavy duty, ultra-precision machines allow for more complete machining of precision components, including precision boring, milling, drilling and tapping. They offer machining centre technology and jig borer precision in one machine.

Specifications:

PJ812 (PJ for “Profile Jig”) with travels X-1,200 mm, Y-800 mm, Z-500 mm. Max work size 1,200 x 800 mm. Table load 1500kg. Spindles are offered from 10,000 rpm to 30,000 rpm. ATC 60, 90, 120 tools.

J1220 with travels X-2,000 mm, Y-1,250 mm, Z-500mm. Max work size 2,200 x 1,500 mm. Table load 3,000 (4,000 opt) kg. Spindles are offered from 10,000 rpm to 15, 000 rpm. ATC 60, 90, 120 tools.

J1230 with travels X-3,000 mm, Y-1,250mm, Z-500mm. Max work size 3,000 x 1,500 mm. Table load 3,000 (4,000 opt) kg. Spindles are offered from 10,000 rpm to 15,000 rpm. ATC 60, 90, 120 tools.

J1625 with travels X-2,500 mm, Y-1,600 mm, Z-500 mm. Max work size 2,700 x 1,700 mm. Table load 6,500 kg. Spindles are offered from 10,000 rpm to 15,000 rpm. ATC 20, 60, 90, 120 tools.