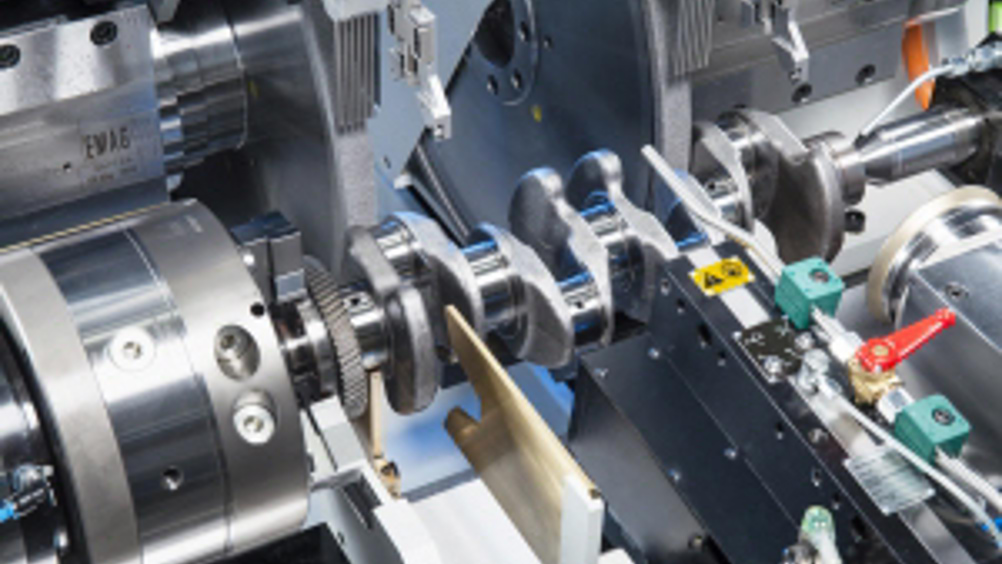

EMAG PMD 2 grinds down crankshaft costs

The PMD 2 crankshaft grinder developed by EMAG Naxos-Union is said to drive down manufacturing costs by delivering higher output rates. It is designed for the machining of crankshafts for passenger cars and features twin grinding heads that allow for the simultaneous grinding of two pin or main bearings in a single set-up, using two CBN grinding wheels. According to EMAG, a four-cylinder crankshaft can be machined in less than 2 minutes.