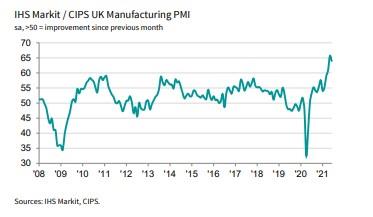

The report said industry was still beset by supply chain and distribution difficulties, however, leading to longer vendor lead times and disruption to production schedules. The PMI dipped slightly to 63.9 in June, down from May's record high of 65.6.

The PMI has signalled an improvement for 13 successive months. Manufacturing production increased at marked rates across the consumer, intermediate and investment goods industries during June.

Growth was supported by strong intakes of new business, which rose at a rate close to May's record high. Improved demand was linked to the ongoing easing of Covid-19 restrictions, re-opening of the economy from lockdown and improving global market conditions. New export orders increased again, reflecting inflows of new work from mainland Europe, the US and Asia.

The strong upswing in global market conditions combined with constraints introduced to combat the Covid-19 pandemic continued to result in considerable supply chain and price inflationary pressures in June.

Average input costs rose at the fastest pace in the survey history, with over three-quarters (77%) of manufacturers reporting an increase. A wide range of raw materials were up in price, including chemicals, electronics, energy, food, products, metals, plastics and timber.

Cost pressures were exacerbated by demand outstripping supply, logistic delays and raw material shortages. The pass-through of higher input costs led to the fastest increase in selling prices since charges data were first collected in November 1999.

Record increases were seen at consumer, intermediate and investment goods producers. Vendor lead times meanwhile lengthened to an extent only surpassed by that seen during the first Covid-19 lockdown in April 2020. Part of the lengthening reflected increased demand for raw materials, as purchasing activity rose at a rate close to May's record high.

Companies linked increased input buying to rising demand and efforts to protect against supply-chain delays and input shortages. The building up of buffer stocks meant that raw material inventories rose at the quickest pace during the year-so-far and to one of the greatest extents in the survey history.

Stocks of finished goods declined sharply as manufacturers settled sales from inventories due to the disruption to production schedules caused by supply-chain delays.

Employment rose at a rate close to May's record high during June. Jobs growth reflected capacity issues – highlighted by near-record accumulation of work backlogs – and optimism among manufacturers. Almost 63% of companies expect production to rise over the coming year, reflecting reduced uncertainty regarding COVID-19 and Brexit and improving global market conditions.