Looser pandemic restrictions and high levels of pent-up demand meant that the rapid revival in labour market conditions continued, with staffing levels also rising at a record pace, according to the PMI.

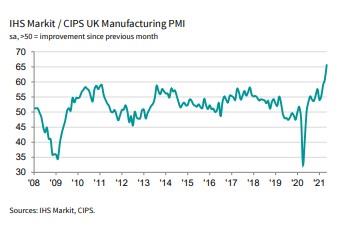

The seasonally adjusted IHS Markit/CIPS Purchasing Managers’ Index (PMI) rose to 65.6 in May, up from 60.9 in April, above July 1994's previous record high of 61.0.

The PMI has signalled improvement in each of the past 12 months. Manufacturing production rose at one of the quickest rates in the series history, bettered only by those registered in August 2013 and July 1994.

Underpinning the latest increase were record gains in new business, as domestic and overseas demand continued to revive. Companies linked new order growth to rising business confidence, the further re-opening of the UK economy and reduced issues relating to COVID-19. New export orders also rose at a survey-record pace in May, amid reports of stronger demand from the EU, the US and China.

That said, there were continued signs that while large companies were seeing record gains in new export work, the rate of increase at small firms was comparatively mild. The corollary of the strong upswing in the performance of the manufacturing sector was pressure building on capacity, with backlogs of work rising to the greatest extent in the survey history.

This was a major factor encouraging firms UK Manufacturing PMI at 65.6 in May production growth strengthens as new work intakes rise at record rate Output prices and input costs rise at unprecedented rates. Data was collected 12-25 May 2021. to reinvigorate their recruitment plans, leading to a record increase in staffing levels at manufacturers.

Pressure also built on suppliers, with the average time taken to deliver inputs to manufacturers lengthening to one of the greatest extents in the survey history. This was linked to input shortages (especially electronics, plastics and metals), transport delays and higher demand for raw materials.

Shortages of raw materials and supply chain disruption fed through to input costs during May, leading to the sharpest rise in purchasing costs since the survey began in January 1992. This led manufacturers to increase selling prices, with the rate of inflation hitting a survey record. Manufacturers' efforts to minimise the impact of supply chain disruption led to a series-record increase in purchasing activity during May.

Rising production needs, building-up safety stocks and guarding against further price rises also contributed to the latest increase in input buying volumes. Inventories of purchases also rose but stocks of finished goods declined as firms used inventories to help meet sales. May saw business sentiment rise to its highest level since data on future activity were first collected in July 2012.

Over 70% of companies forecast that production would be higher in one year's time, compared to only 3% expecting a decline. Improved optimism reflected the end of the pandemic, economic recovery, planned business expansions, a revival in World trade flows and reduced supply-chain issues.

Duncan Brock, group director at the Chartered Institute of Procurement & Supply, said: “A month of survey records, as the manufacturing sector not only held its ground, but increased its share of productivity for the UK economy with higher levels of orders, job creation and optimism.

“Leading the way to this growth was continuing strong domestic demand but the level of export orders was a high point with a return from European, US and Far Eastern customers growing pipelines at the highest levels since at least 1996. The ongoing boost in job numbers was an attempt to build capacity to meet this surge as backlogs increased steeply and delivery times grew to unsustainable levels, pulling back on further progress in fulfilling orders.

“The march of the makers has turned into a sprint as the blocks of lockdowns have been removed, but we haven’t seen this level of price inflation on materials for decades. Supply chain managers anticipate a continuing squeeze on deliveries and are forward buying and building stocks, so we may not have seen price peak yet. This means bigger inflationary pressures for the wider economy and the country’s place in international trade as prices charged also rose at record rates.”