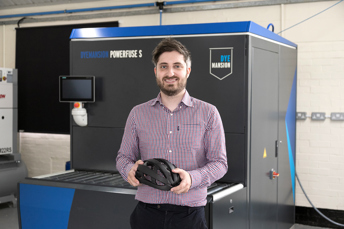

Wetherby-based All 3D Labs has invested in an HP Multi Jet Fusion 5200 3D printer and become the first service provider within the UK to purchase the German-manufactured Dyemansion Powerfuse S finishing machine.

All 3D Labs is a 3D printing company providing a more sustainable, more accessible, and digital way of manufacturing.

The company offers services from prototyping to low volume production runs. Parts can be made within four to five working days. Customers use a free online quotation system, giving them an instant quote for their parts.

Mark Baresh, founder of All 3D Labs, explained: “Investing in this new machinery will help our customers transform how they turn 3D-printed parts into end-user parts.

“The Powerfuse S is a game-changer as it allows our customers to create 3D printed parts with injection moulded like finish with enhanced surface qualities.

“The machine uses a VapourFuse Eco Fluid, an environmentally friendly solvent that processes plastics according to food contact regulation (EU) 10/2011. This opens the doors into new fields of real-world food and beverage applications.

“3D printing can empower teams to transform and innovate their existing business model. One of the innovations we’re most proud of at All 3D Labs is helping our customers switch to a more digital way of manufacturing, with a greener and more sustainable way of making their products. Our printing process recycles up to 80% of unused material.”

Mark continued: “3D printing is already changing how we make products, from medical devices to automotive parts. But an increasing number of organisations are now exploring how 3D printing can help them deliver a better quality end product within days, rather than months.

“In the past, the only option for businesses was to go through the lengthy process of cutting tooling, injection, moulding, and finally delivering the product. This would normally take several months. By contrast, All 3D Labs’ customers simply send their designs through our website and get a fully functional part in 4 days. Customers can send their existing 3D-printed parts to be vapourfused, and we do the rest.

“In addition, we enable 3D printing to move from rapid prototyping to end-user parts and that’s a big game-changer for our customers.”

Joseph Bellis, additive manufacturing sales manager at Matsuura Machinery Ltd, the distributor of the HP Multi Jet Fusion 5200 3D printer and Dyemansion machinery, comments: “We’re delighted that All 3D Labs has become the first service provider in the UK to offer the Powerfuse S in conjunction with HP 5200 3D printer.

“The new technology will transform the range of products All 3D labs can offer customers, and we wish Mark and the rest of his team all the very best as they continue to develop their company.”

Colin Glass, who has been advising All 3D Labs since its inception, said "With start-ups, the key to success is the ability of the entrepreneur and his resilience when challenges arise. I’ve been most impressed with Mark's determination in successfully raising the significant funding required to acquire the machinery to operate a modern 3D Bureau. We’re also very grateful for the tremendous support and assistance from Matsuura."