MTL develops cost-effective cold-forming armour plate bending process

1 min read

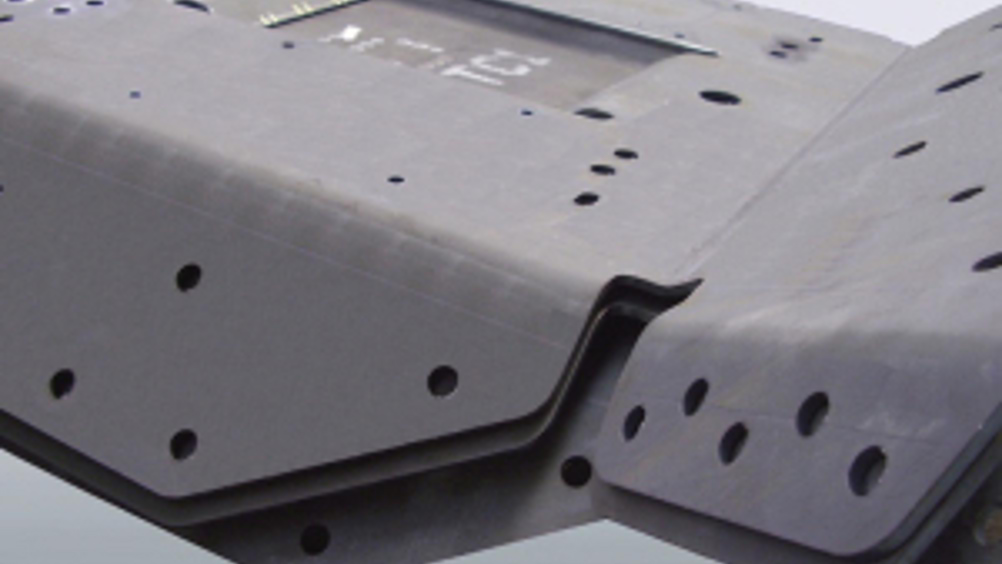

MTL Group has announced the launch of a new technology called SMARTbend, which allows the armour plate specialist to form intricate shapes without the need for expensive tooling. The technology will be on public display during DVD 2013, running from 19 to 20 June at Millbrook, Bedfordshire (see link below).

Following on from the success of the company's IMPAS Armour solution for add-on protection up to STANAG 4569 Level IV, MTL Group has invested significantly in SMARTbend, giving armoured vehicle manufacturers a lower cost cold-formed solution as an alternative to hot-formed armour.

As no heat is introduced into the material, the original mechanical properties of the steel are maintained, unlike other processes that rely on heat and expensive, bespoke tooling to bend this type of material.

Simon Hurst, sales manager for defence at MTL Group said: "Our customers are always challenging us to offer new options for their current vehicle protection systems. We work with them to manufacture an armoured structure in fewer pieces giving a stronger, lighter and more cost-effective product, together with increased protection levels to the end user.

"It is an exciting and busy time for MTL Group at the moment, with more customers bringing their challenges to the table ranging from hull optimisation projects to weight and cost reduction programmes and they are seeing excellent results."