Supplied by the Southam, Warwickshire- based Engineering Technology Group, the UX 600 is currently the largest fully simultaneous Quaser vertical 5-axis machine operating in the UK.

Metalite makes injection mould tools, some of which require multiple set-ups across a number of different machines.

Operations manager Michael Watts explains why the company has installed the Quaser: "Our five Hardinge XR 1000 3-axis VMC machines are the work horses of our operations but if you take an injection mould tool, it typically starts on a 3-axis VMC, then moves on to a 5-axis and, finally, undergoes horizontal boring on another machine. Given our heavy workload, this can cause problems with machine scheduling and create delays that customers find unacceptable. The full 5-axis capacity of the UX 600 is helping overcome these bottlenecks, as we can now genuinely manufacture tools to an advanced stage in a single set-up."

Photo: The swivelling rotary table 5-axis UX 600 has increased the efficiency of Metalite's machine shop throughput.

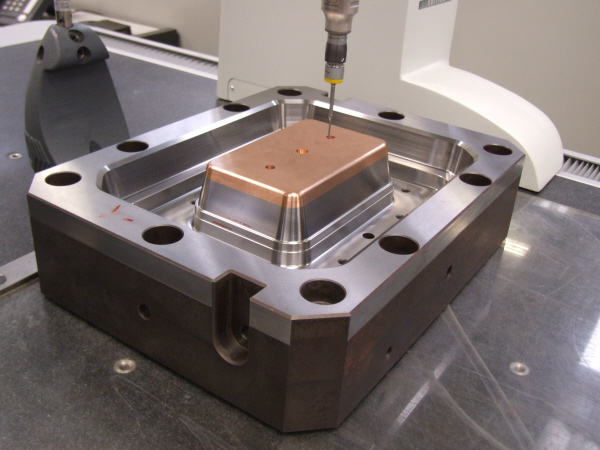

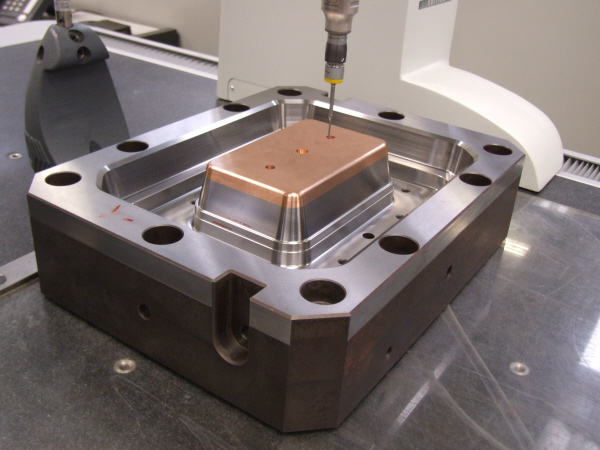

Photo: A die mould core like this is now machined in a single 'op' on the Quaser UX 600.

Metalite's operator's (below) have found the Quaser machine very user friendly, as it is equipped with a Heidenhain ITNC530 control (compatible with the existing Hardinge VMCs). Once Metalite's programmers have accepted the customer's solid model, the lead time in programming is kept to a minimum. The operators have described the transition to a 5-axis machine as "seamless".

Although already a high specification machine, Metalite opted for a higher speed (15,000 rpm) spindle and the larger capacity (60 tool) ATC. Other standard features include 20 bar through-spindle coolant, unique clean grease spindle lubrication every 70 hours, plus very high thermal stability in the head stock and ball screws that maintain 4 micron repeatability in X, Y and Z axes.

"Virtually everything we do is classed as a one off, so flexibility, capability and capacity are all equally important," explains managing director Michael Watts. "The efficiency over moving multiple projects around the machine shop is vital; we need efficiency without compromise and this new Quaser is already becoming a cornerstone of our operations."

Photo: The swivelling rotary table 5-axis UX 600 has increased the efficiency of Metalite's machine shop throughput.

Photo: The swivelling rotary table 5-axis UX 600 has increased the efficiency of Metalite's machine shop throughput.

Photo: A die mould core like this is now machined in a single 'op' on the Quaser UX 600.

Metalite's operator's (below) have found the Quaser machine very user friendly, as it is equipped with a Heidenhain ITNC530 control (compatible with the existing Hardinge VMCs). Once Metalite's programmers have accepted the customer's solid model, the lead time in programming is kept to a minimum. The operators have described the transition to a 5-axis machine as "seamless".

Photo: A die mould core like this is now machined in a single 'op' on the Quaser UX 600.

Metalite's operator's (below) have found the Quaser machine very user friendly, as it is equipped with a Heidenhain ITNC530 control (compatible with the existing Hardinge VMCs). Once Metalite's programmers have accepted the customer's solid model, the lead time in programming is kept to a minimum. The operators have described the transition to a 5-axis machine as "seamless".

Although already a high specification machine, Metalite opted for a higher speed (15,000 rpm) spindle and the larger capacity (60 tool) ATC. Other standard features include 20 bar through-spindle coolant, unique clean grease spindle lubrication every 70 hours, plus very high thermal stability in the head stock and ball screws that maintain 4 micron repeatability in X, Y and Z axes.

"Virtually everything we do is classed as a one off, so flexibility, capability and capacity are all equally important," explains managing director Michael Watts. "The efficiency over moving multiple projects around the machine shop is vital; we need efficiency without compromise and this new Quaser is already becoming a cornerstone of our operations."

Although already a high specification machine, Metalite opted for a higher speed (15,000 rpm) spindle and the larger capacity (60 tool) ATC. Other standard features include 20 bar through-spindle coolant, unique clean grease spindle lubrication every 70 hours, plus very high thermal stability in the head stock and ball screws that maintain 4 micron repeatability in X, Y and Z axes.

"Virtually everything we do is classed as a one off, so flexibility, capability and capacity are all equally important," explains managing director Michael Watts. "The efficiency over moving multiple projects around the machine shop is vital; we need efficiency without compromise and this new Quaser is already becoming a cornerstone of our operations."