The facility now sports a brand new DMG Mori NVX 5080 milling machine (working area: 800 by 530 by 510 mm) and Mazak Quick Turn Smart 350 lathe. They complement an older 5-axis twin-pallet Mazak Variaxis 730-5x II.

In the seminar room, sales director David Jones explained the context for the new machines: “Engineering is a very important part of what we do now. We have a project engineering team and a product engineering team, all time-served. What we do now is all about continuous improvement.” The facility employs 96 people in product and project engineering, and process development. He added: “All of the machines we’ve purchased are for the use of our customers; they’re not just there for us to make swarf. They’re for testing and improving processes. In the past we’ve done batch production and first-off, pass-off and inspection.”

He stressed that the company now adopts a collaboration model, bringing in other suppliers of machine tools, software and workholding to provide an entire solution to customers looking for help with metalcutting challenges.

New DMG Mori milling machine

New DMG Mori milling machine

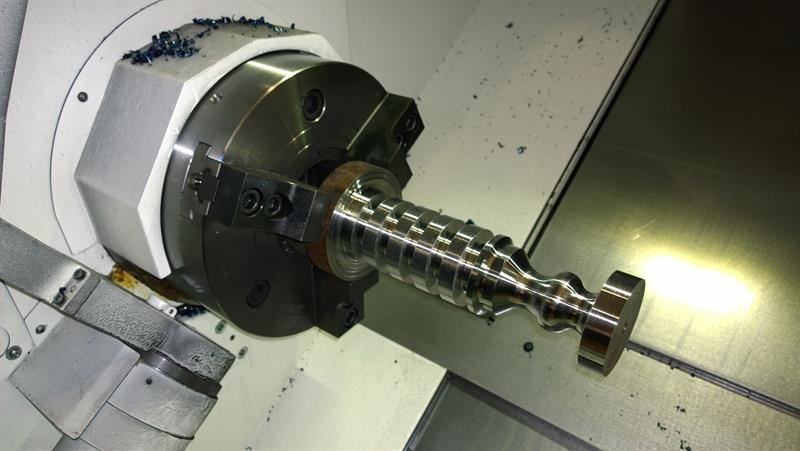

A popular demonstration on the new lathe was dry turning on EN24T alloy bar using the GrooveTurn insert (speed: 180 m/min; feed: 0.77 mm/rev) and subsequent grooving (speed: 180 m/min; feed: 0.25 mm/rev, to 15 mm depth), using the DoveIQTurn heavy duty line of inserts with scalloped edge.

Sample of dry grooving in EN24T on new Mazak Quick Turn 350

Also new on site is a dedicated tool presetting area, said Jones: “Our market is developing in such a way that we are now supplying fully-assembled pre-set tooling for turnkey projects. It’s not just about ‘Here’s a packet of inserts, here’s a toolholder, here’s a spindle tool, here’s a pull stud.’ We’re now doing full assemblies, fully assembled, measured, labelled, ready to go into the machine tools when we take them on site.” This facility features a Kelch tool presetter; another is available for use in the customer area. It is adjacent to an area supporting the company's Matrix tool vending machine systems that allow tool supply 24 hours a day. New tool presetting area featuring Kelch equipment

New tool presetting area featuring Kelch equipment

Highlights of the wide range of turning, milling and drilling tools on show include the SumoCham, CombiCam and CamIQ steel drills; all take a formed carbide insert at the tip. Milling inserts shown include the double-sided, four-edged HighQLine IQ 845 with wiper for finish cuts, six-edged HM690 shoulder mill; the 16-edge HeliOcto facemill cutter; HeliDo button insert for mould countours; 2-sided HeliAlu high speed milling inserts; and the IQ Intelligent Machining H606 button profiling tool that includes a straight edge as well as curved edge for contours.

UPDATED 25 January 2016: Cropped DMG Mori picture, reorganised middle of article