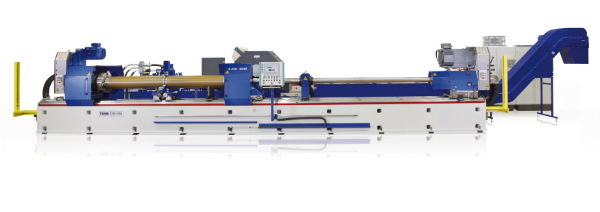

With this, the Leighton Buzzard-based machinist has increased production capacity, as well as extended the scope of its boring service from an existing 200 mm diameter by 2.8 m deep capability to one of 250 mm diameter by 3.2 m deep. The latter is supported by a TIBO B250, while a TIBO B80 will similarly deliver bores of up to 3.2 m depth, but has a maximum diameter capacity of 80 mm.

The investment will mean that diameters beyond 200 mm diameter are drilled in a single pass rather than three or four, reducing cycle times by upwards of 75%. In addition, the TIBO B250's robust structure will also improve precision and surface finishes, says Hone-All.

A reduction in billet pre-machining is also gained through the investment, as the TIBO Tiefbohrtechnik machines can undertake boring without the need for such operations. Explains the subcontractor's director, Andrea Rodney: "At Hone-All, all large billets would pass through the turning department for a pre-boring 45° chamfer, prior to loading on the boring machines. This will no longer be the case. The sheer size of the billets and the logistics meant that we could be losing up to 40% of our CNC turning capacity each month. The new TIBO machines will allow us to machine sawn billets with no pre-machining, so we instantly gain 40% capacity in the turning department."

Of the investment overall, she says: "We have witnessed exceptional growth in the last couple of years from customers in all industry sectors and the new machine investment will enable us to alleviate any capacity issue whilst providing the opportunity to win new business previously beyond the capabilities of our plant list.

"Our size restrictions limited our ability to quote for jobs and we were losing work that was just beyond the size limits of our existing machines. The new TIBO machines will increase our productivity, sales, capacity and extend our product offering for end users.

"Simultaneously, we will reduce our costs, cycle times, energy consumption and eliminate any inefficiencies throughout the deep hole boring department."