Forcam Force, the software that provides the crucial information flows and analysis for Industry 4.0, is said to deliver productivity gains of 20% or more during the first year, providing the basis for on-going performance tracking and continuous improvement.

UK MD Andrew Steele notes: “We are delighted to be in Hall 5, with the machine tool companies and the visitors from capital intensive plants who really can benefit from our system. Tracking plant outages, sub-optimal cycle times, material or quality issues in real-time is just part of the story. What really excites managers is that this information from Forcam Force feeds directly into their ERP system, where real-time data is of immense value to the whole enterprise.”

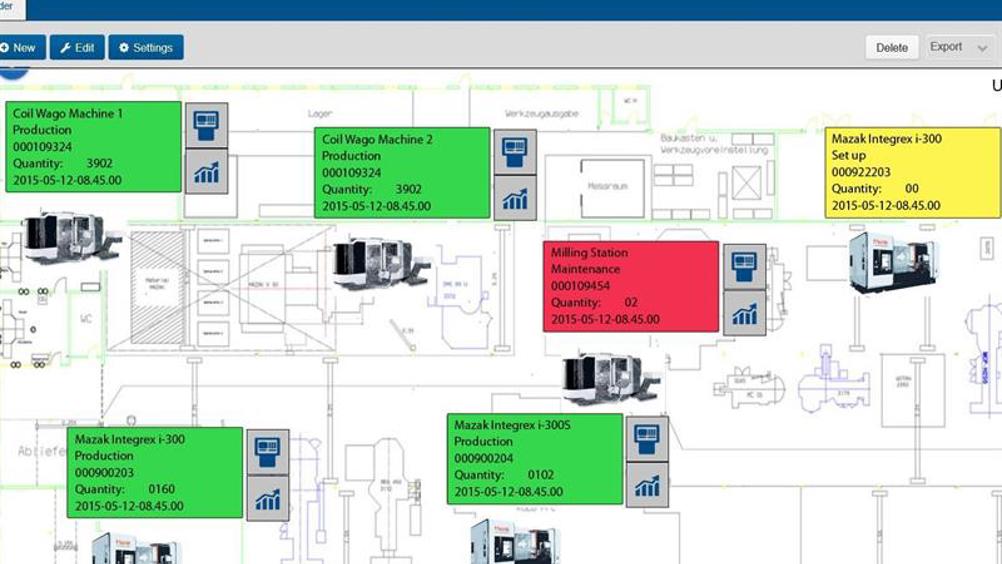

In keeping with the MACH theme of ‘Manufacturing in Motion’ Forcam will have a live model manufacturing cell on the stand to record work in progress as components pass from one workstation to another. Visitors will see how the system gathers real time information and generates instant customised reports.

To speed the transition to Industry 4.0, the company has produced a starter kit – Smart Factory in a Box – for low cost, low risk trial. “Forcam Force is used by leading automotive, aerospace, and engineering producers. At MACH we can share our experience and show that Forcam Force is not just an aid to productivity but a method of working that engages and benefits the whole team,” concludes Steele.

Forcam demonstrates the benefits of machine interconnectivity at MACH (stand 5060)

Shop floor productivity software specialist, Forcam, is showing how the interconnection of machines to gather production information and provide real-time data boosts production performance.