Matt Farnsworth, aero structures platform group leader at the AMRC, says: "Delcam allows us to be on the machine cutting a lot quicker than the alternative software solutions because we're able to reduce our programming times.

"We also use on-machine verification with PowerINSPECT so, when we are getting near to finishing a part, we can probe the surfaces and machine adaptively, if required, to ensure that we get good geometrical tolerances."

Matt Farnsworth, aero structures platform group leader at the AMRC, says: "Delcam allows us to be on the machine cutting a lot quicker than the alternative software solutions because we're able to reduce our programming times.

"We also use on-machine verification with PowerINSPECT so, when we are getting near to finishing a part, we can probe the surfaces and machine adaptively, if required, to ensure that we get good geometrical tolerances."

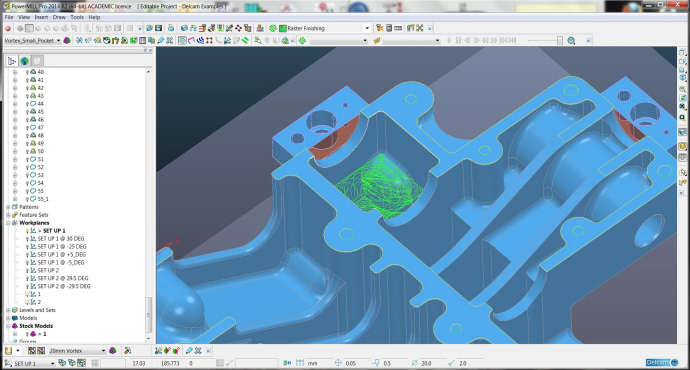

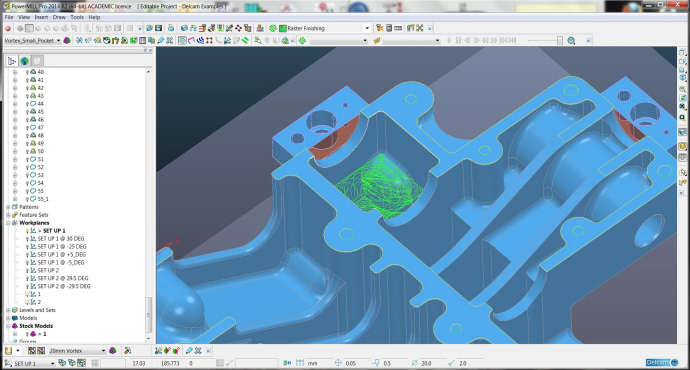

Delcam’s Vortex speeds up the machining of Bloodhound car parts

The Vortex function in Delcam's PowerMILL software is dramatically speeding up the machining of components for the Bloodhound supersonic car project.

Matt Farnsworth, aero structures platform group leader at the AMRC, says: "Delcam allows us to be on the machine cutting a lot quicker than the alternative software solutions because we're able to reduce our programming times.

"We also use on-machine verification with PowerINSPECT so, when we are getting near to finishing a part, we can probe the surfaces and machine adaptively, if required, to ensure that we get good geometrical tolerances."

Matt Farnsworth, aero structures platform group leader at the AMRC, says: "Delcam allows us to be on the machine cutting a lot quicker than the alternative software solutions because we're able to reduce our programming times.

"We also use on-machine verification with PowerINSPECT so, when we are getting near to finishing a part, we can probe the surfaces and machine adaptively, if required, to ensure that we get good geometrical tolerances."