The two companies have entered into a strategic development partnership to deliver an innovative automated guided vehicle (AGV) system to work with Concept Laser’s M Line Factory concept (detailed below*).

Success will see Concept Laser become the first manufacturer of machines and installations for 3D AM to embrace an automation solution and will see M Line Factory modules moved between different machine units and within the production environment.

Concept Laser's M Line Factory now aims to have AGV transport of modules between machines

Concept Laser's M Line Factory now aims to have AGV transport of modules between machines

Swisslog’s AGV system is regarded as a key strategic element the M Line Factory. Swisslog’s task is to integrate a driverless transport system with smart software for fleet management and power supply to ensure that modules can be moved between different machine units or within an AM factory.

The planned approach pursues two objectives: AGV movement of modules between machine units or within a production environment; the reliable and automated supply of powder material and preparation.

Says Dr Florian Bechmann, head of research & development at Concept Laser: “The ambitious concept of the M Line Factory ensures a high level of automation and flexibility in 3D metal printing. The AGV system from Swisslog is the next stage in the development toward consistent automation of the processes embracing the basic idea of ‘Industry 4.0.’”

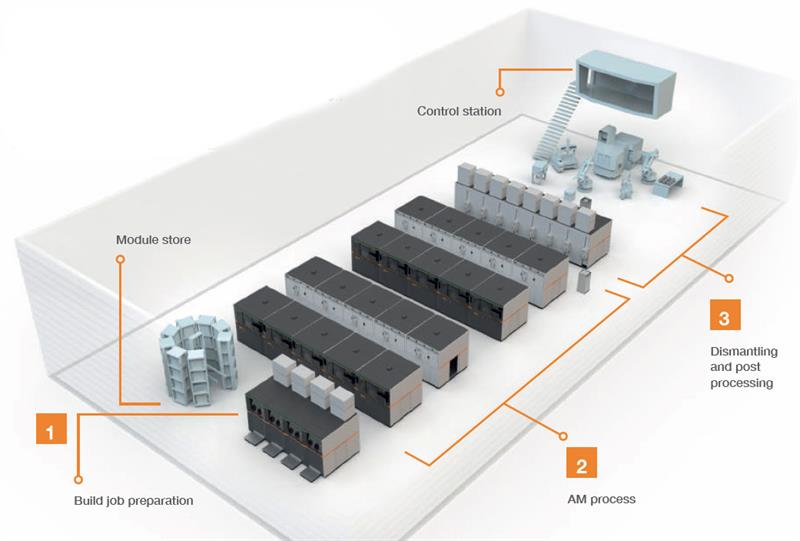

* The M Line Factory is a modular machine architecture that decouples part production from set-up and dismantling processes, so that these processes can take place in parallel, rather than sequentially. This new architecture consists of two independent machine units: the M Line Factory PRD and the M Line Factory PCG

Concept Laser M Line Factory - PCG unit, left, PRD unit, right

Concept Laser M Line Factory - PCG unit, left, PRD unit, right

The M Line Factory PRD is the production unit and consists of three modules: dose module, build module and overflow module. All of these can be individually activated and do not form one continuous unit. These modules are transported via a tunnel system inside the machine. For example, when new powder is supplied, the empty powder storage module can be automatically replaced by a new module, without interrupting the build process. Finished jobs can be moved outside of the machine and automatically replaced to resume operations immediately.

M Line Factory PCG is an independent processing unit that has an integrated sieving station and powder management. Unpacking, preparations for the next build job and sieving take place in a self-contained system without the operator being in contact with the powder.