Set to begin operating in 2020, FutureForge will be the world’s most advanced hot-forging research platform and include a one-of-a-kind, industry 4.0-ready demonstrator. The facility will enable the AFRC to work with companies in the aerospace, automotive, energy and rail industries, helping to increase their global competitiveness.

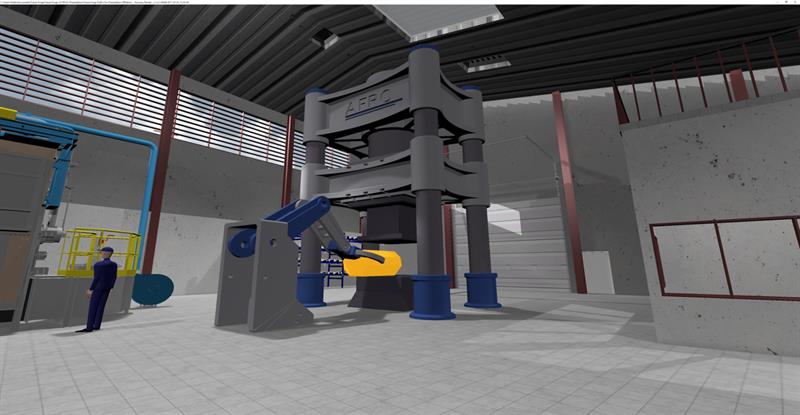

Photo: The new facility wants to transform hot forging into a competitive industry with advanced digitised capabilities

Ivan McKee, the Scottish Government’s Minister for Trade, Investment and Innovation, says: “The new facility will put Scotland at the forefront of the latest industrial revolution, helping some of the most traditional manufacturing businesses and their supply chains embrace the latest in digital technologies. When I visited the centre last month, I was able to hear first-hand how the funding will be invested to develop this world-leading technological capability.”

Professor Sir Jim McDonald, principal and vice-chancellor of the University of Strathclyde, is equally pleased, adding: “This new facility will be a real asset to the AFRC and its business partners, and demonstrates Strathclyde’s commitment to working together with industry on research, development and innovation.”

Executive chair of the AFRC, Professor Keith Ridgway, says: “This is the third big announcement in the past year and Scotland’s reputation as being the go-to place for the development of the next generation of manufacturing technologies is strengthening. The FutureForge facility will see us transform the $268 billion global forging supply chain, taking it from a black-art with centuries of tradition and turning it into a competitive industry with advanced digitised capabilities fit for centuries to come.”