Despite being a key component of manufacturing and engineering quality – "whatever is manufactured has to be measured", says Mitutoyo UK director Martin Weeks – industry has, sadly, ignored the need to train people in the basics of metrology. But opportunity to put this right is on offer, with major new training programmes launched in 2014 and early 2015.

After about two years of development, Mitutoyo UK (01264 353123) launched a dimensional metrology training course in November 2014 that is the first to be accredited by training body City & Guilds. City & Guilds has a "marvellous" reputation and is well-recognised on the shopfloor, says Weeks, and the qualification offered fits with its existing qualifications in other areas of metalworking manufacturing, including milling, turning and grinding.

Students take a mandatory one-day introduction course and then at least one of seven follow-on courses, ranging in subject and duration, including using small dimensional metrology instruments (one day) to using a contact coordinate measurement machine (five days). Those who successfully complete two units of training gain a City & Guilds Level 2 award.

"We found it difficult to get people to participate in courses that from the outset call for a high understanding of the subject matter, as even for time-served engineers this has proved a weakness," Weeks says; but not this one. "Our course starts from the basics of a steel rule and progress through to the appliance of, say, 3D measurement."

Martin Weeks, Mitutoyo UK director, has held a 'lifelong ambition' to raise the status of metrology knowledge in industry

FOCUS ON FUNDAMENTALS

He highlights that the course's focus on fundamentals is novel. Traditionally, if someone bought a Mitutoyo product, they would receive training more weighted towards product operation. "Now we are addressing the balance in helping people understand more of the subject matter, the 'metrology' behind what they are doing and, thus, it's not simply Mitutoyo product-based. It is like taking your [driving] test in a Jaguar; you may pass, but you don't have to use it [a Jaguar] for the rest of your life."

Mitutoyo UK's director was intimately involved in developing the course andsays that getting recognition of the importance of metrology in the industry has been a "lifelong ambition". He adds that it is "frustrating" to witness how poorly the valuable skill of metrology is often treated. Employers have also suffered by lacking the ability to formally identify engineers with specific metrology skills, he suggests.

The first eight trainees passed through the course in November; the roll-out effort moved up a gear in the new year.

The company is also planning partnerships to deliver the training; some of the new University Technical Colleges (www.utcolleges.org) have been particularly interested. Weeks highlights that the metrology course slots right in with the curriculum of the engineering-slanted government-funded schools for 14-18 year-olds. But interest has come from across industry, he reveals.

Looking forward, Mitutoyo is considering two possible directions for future development: a Level 3 qualification, or possibly extending internationally. "We're a global operation, in 80 countries. That's the same as City & Guilds. We're therefore looking not just at the UK, but further afield." Other Mitutoyo operations in Europe, and elsewhere, are also enquiring about it, Weeks concludes.

Mitutoyo's new courses may be incorporated into the curriculum at some UTCs

Also looking internationally is the UK's National Physical Laboratory (NPL) (http://is.gd/racjxq), which is launching a dimensional metrology course that is largely delivered online. The course of six modules is intended to take two or three days – although reading all the background materials could extend it more. And, unlike other e-learning courses, the third day sees face-to-face exercises and assessments, undertaken at some of NPL's network of six centres in the UK (although the delivery network is still being finalised).

When the project started in mid-2012, not only were UK customers looking for a different kind of training that was more flexible to adjust around their schedules, but there was worldwide interest as well. André Silva, NPL training e-learning manager, says "there was an actual need to reach those markets we couldn't get to", through NPL's physical training network.

The e-learning option also helps minimise a customer's travel and accommodation costs, he adds. "Before, our customers were asking us to make the sessions shorter and shorter, while producing the same skills, and that's very difficult. This is an elegant solution to that problem, we believe."

The first job was to build the internal processes to develop the content, consulting with internal subject-matter experts from academia and industry, and tailoring the material so it is easy to understand but progresses through the subject.

First to launch in the new format, in late 2013 and then April 2014, are bestsellers in NPL Training's conventional offering: Introduction to Metrology and Introduction to Measurement Uncertainty. These courses consist of rich media (not just text), with training materials accessible by a standard computer with internet access. The course guides the student through the material automatically, although the pace of progress is set by the learner. Each of these courses, which generally take half a day to a day to complete and are divided into several modules.

FREE ONLINE COURSES, TOO

NPL has also published several free courses online: Measurement Fundamentals Explained and Measurement Uncertainty Explained; a free glossary of metrology terms is also available.

Because it is hard to know who is actually sitting in front of a computer taking an e-learning course, NPL only offers these customers a certificate of completion. To offer students the possibility of receiving an accredited qualification, NPL's new 'blended learning' course on dimensional metrology includes a final face-to-face component.

This session gauges students' depth of understanding of the material and teaches them practical skills, says Silva.

It starts with a classroom assessment, to see if students have completed the e-learning course, and then five practical exercises to explore course topics with actual measurement tools. The final module introduces students to a task checklist suitable for any kind of measurement work, while a final exercise that is the most complex sees its solution and methods discussed with students, NPL's Silva explains.

The first five modules are now available online; the next face-to-face day is scheduled for April. Learners have a month to access all of the course materials. NPL Training is initially planning to provide seven face-to-face training sessions in 2015 to cater for launch demand.

Meanwhile, NPL Training continues to offer a range of face-to-face courses in metrology, ranging from an introductory level (1) to expert level (4). Topics include dimensional metrology, laser safety, portable coordinate measurement systems and geometrical dimensioning and tolerancing. Training is delivered by approved delivery partners. In the UK, these are: Coventry University, Exova Metech, Faro, Hexagon Metrology, Iain Macleod Associates and Mitutoyo.

NPL also has delivery partners in China, Singapore, Scandinavia and the United States. The NPL Training framework is accredited by EAL (Excellence, Achievement & Learning Ltd) and validated by the National Skills Academy for Manufacturing (NSA-M). That means that those people who successfully go through its courses earn a national qualification.

He concludes: "Talking with academia, they say 'metrology is great', and industry says the same, but our students don't come from university with a knowledge of metrology; universities are not covering this topic, so we have a gap, and national metrology institutes are in a position to support that. Instead of solving problems in industry, students should solve metrology problems before they get there."

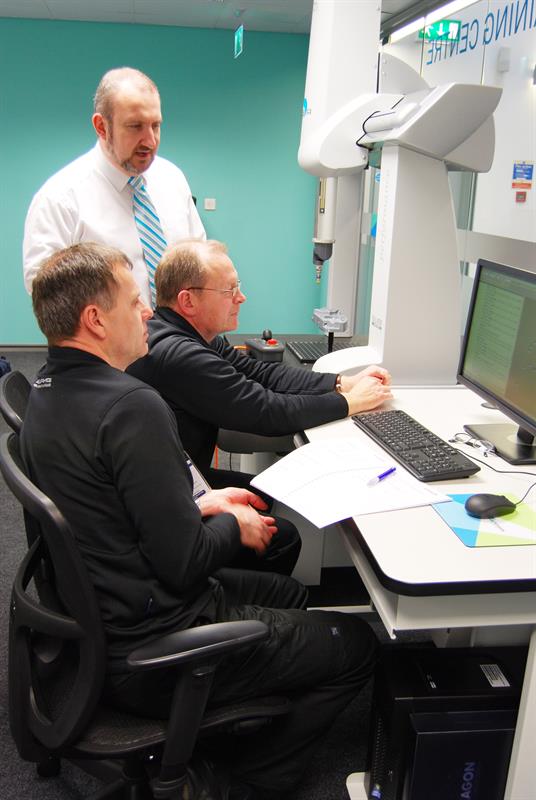

Hexagon Metrology offers one-day training in refurbished facilities in Telford and Milton Keynes, and beyond

INTRODUCTORY COURSE ROLL-OUT

Another partner of NPL is Hexagon Metrology (http://is.gd/Y7ZQ8X), which rolled out four new one-day introductory courses during last year. Although the company is an accredited delivery partner for NPL's training courses, their three-day length was too much for some customers, says Sam O'Prey, Hexagon Metrology aftermarket sales manager, UK & Ireland.

Customer surveys in 2014 pointed to "a lack of knowledge in basic skills", says O'Prey. It is now offering Introduction to Dimensional Metrology, Introduction to Coordinate Metrology, A Practical guide to Measurement Uncertainty, and Calibration and Gauge Maintenance. As of mid-December, 40 people had attended.

The new foundation courses, which cost £995 for the first four people (maximum capacity 12), are delivered at refurbished facilities in Telford or Milton Keynes, at the Advanced Manufacturing Research Centre in Sheffield, Huddersfield University, or at customers' premises.

O'Prey says that the company is encouraging its customers to enrol staff on one or more introductory metrology courses before taking Hexagon's training courses for its metrology software, PC DMIS.

To further improve basic customer competence it bought 200 seats of two NPL e-courses, Introduction to Metrology and Introduction to Measurement Uncertainty, and has been offering them for free to new machine customers. "We get the results back from NPL, and get an idea of their skill level before they come to training," O'Prey concludes.

NPL tolerancing course helps designers help people

Two design engineers at a manufacturer of mobility aids for children Smirthwaite recently completed an NPL training course on geometrical tolerancing.

Deasign engineer Phil Kidd says: "We produce Class 1 Medical Devices – daily living aids, such as seating and standing equipment. Whilst these are not as highly controlled as Class 2 Medical Devices, such as surgical tools, there are regulatory procedures and guidelines that designs need to comply with."

The training is helping Kidd and a colleague in the production of engineering specifications on a daily basis and to control various parts of their designs more efficiently by correctly specifying the geometrical properties of features.

Explains Kidd: "Our drawing and engineering designs are now reaching a much higher standard and also saving time in production, there is far less ambiguity."

He provides this example: "A recent sheet metalwork drawing noted lots of dimensions but no geometrical tolerances. We can now apply those, making the drawing much simpler to read. It's a step forward from older style drawing and will benefit everyone involved."

[Article updated on 5 March 2014]