Since being launched in the bedroom of a house in the ‘steel city’ of Sheffield, Ceratizit UK & Ireland – formerly WNT (UK) Ltd – has now risen to the top of the UK and Ireland cutting tool market and this month, it celebrates its 25th anniversary of being in business.

Managing director Tony Pennington launched WNT (UK) Ltd on 22 November 1999, after he had first registered the company earlier that year as an ambitious 28-year-old.

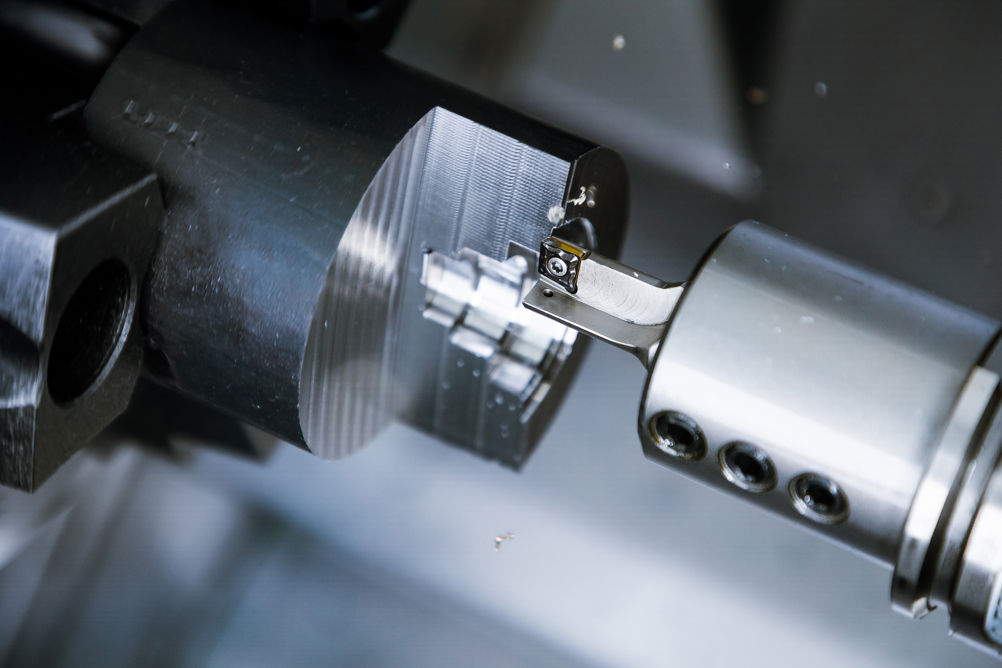

WNT UK started out providing HSS drills, solid carbide drills, indexable drills, reamers and countersinks, taps and dies, thread milling cutters, thread turning tools, turning tools, miniature turning tools, parting and grooving tools, high-speed steel milling cutters, solid carbide milling cutters, indexable milling tools, spindle nose tooling and workholding products. ‘Everything from the spindle nose to the machine table and from the turret to the chuck.’

“The company was formed in the spare bedroom of my first family semi-detached home in Stannington, north of Sheffield,” Tony remembers fondly. “I started out on my own with zero customers and zero turnover and I started to set the company up after I was given £1m of share capital from our parent, Plansee Group, into a Deutsche Bank account.

“The first catalogue was in a binder format and it was translated with the Birmingham Chamber of Commerce from German to English and printed in Norwich.

“WNT had been operating in Germany with a catalogue for about 12 years and the Plansee Group decided that they wanted to see if that concept could be successful in other locations, starting with the UK,” says Tony.

WNT (UK) Ltd was part of parent company the Plansee Group, before Ceratizit was created in 2002 after the merger of Cerametal and Plansee Tizit to form Ceratizit S.A.

Development of the company during the last 25 years has been at a rapid pace, but Tony’s view is that one of the keys to running a successful business is that as you evolve, you must always remember and continue to do the good things that have made you a success, never forget where you have come from and build on that foundation of success and core values.

“Everybody has to have quality products,” he says. “Our products are top quality like the other major manufacturers, but what we have is our unique service offering to customers.”

The complete package consists of technical support from engineers, not salesmen, a catalogue focused only on metalcutting, but covering everything to provide a one-stop shop for metalcutting, 98% ex-stock availability across 100,000 metalcutting products, late ordering until 6pm with free guaranteed next day delivery before noon, in-house supplied and supported vending systems, Made in Sheffield bespoke fixturing and workholding, and recycling of used carbide tools back into our production.

“All these things and more are aimed at making our customers’ lives easy with regards to cutting tools so they can concentrate on machining and adding value to their businesses,” says Tony.

People power

The foundations of success at Ceratizit UK & Ireland over the last quarter of a century since its establishment are its people, and Tony has always worked on the values that “people and the team make the difference”.

The company started out with only one employee, Tony, before he then quickly grew the team to 18 – nine sales staff, all engineers, who were out on the road and nine employees in the office.

Ceratizit UK & Ireland now employs more than 70 staff including 42 engineers, with most staying on for many years and the average length of service being 13 years. Indeed, 37 of its employees have more than 10 years’ experience and 16 have actually served more than 20 years.

“Our people are so important and having a team with long-term service and commitment to customer service over many, many years is so critical – as it develops long-term relationships and trust with the customers and employees,” he explains.

Top logistics

Another key part of the strategy over the last 25 years at Ceratizit UK & Ireland since the business was established has been to ensure that it is number one at logistics in the market, and it was something Tony focused heavily on right from the very start.

Ceratizit UK & Ireland’s first advertisement, when it was WNT UK, was centred on ‘Total Tooling Solutions’ and ‘Speed of delivery’ – logistics has always been a major driver of the business. “In all our customer satisfaction surveys, logistics was always our number one differentiator,” notes Tony.

“Basically, our philosophy has always been to have the right tool available at the right time, whether that be through having the product on site for the customer 24/7 with our vending systems or ordering it by 18:00h for delivery before noon the next day guaranteed. This has always been the best logistics in the industry for over 25 years,” says Tony.

The arrival of Brexit in 2021 threw a spanner in the works of the logistics operations for all UK companies and indeed, for Ceratizit UK & Ireland too.

This caused a major blip, as it had to figure out a new strategy to overcome the challenges and ensure its logistics was still the best in the UK cutting tool market.

A hybrid logistics strategy was implemented to overcome challenges that included the most popular tools held in Sheffield, free guaranteed next day delivery over £50, a Saturday delivery and same-day delivery services, and a new trade counter was also set up where cutting tools can be picked up by customers in person.

His solution was centred around the company’s very successful special selection brochure that has been an integral part of the company for the last 24 years.

This is still printed and mailed every three months to customers and is also now available in digital format. The brochure covers a range of the most commonly used tools with the vast majority stocked in Sheffield. If the product is marked with the UKS logo (UK Stock) in this brochure then it is held in Sheffield.

“This makes it easy for the customers and our technical sales engineers to know what is in stock in Sheffield for guaranteed same-day despatch and next day delivery before noon,” explains Tony.

If products are not in stock in Sheffield, they will be delivered via an Express service from Germany with dual shipping allowed to ensure high customer service and satisfaction.

Vending growth

Today, a key part of logistics is the ever-expanding tool vending systems, which Ceratizit UK & Ireland are installing at a rapid rate across the UK & Ireland.

Starting with their first vending machine installation in 2002, they now have over 500 vending machines installed with customers across the breadth and depth of the UK & Ireland.

These are bringing many benefits to users, as they can keep a tight grip on tooling costs with ease and concentrate on machining and adding value to their business, not cutting tools.

The vending machine operations are run by a back-office team of five in Sheffield and a field-based installation and replenishment support team of six.

Whilst intelligent computer systems are running dynamic stock management systems for the majority of customer usage and demand, this is overlaid by the back-office team who are proactively looking every hour, every day at the customers’ vending stock and managing stock increases where necessary, closely liaising with the field-based team and customers to ensure a continuous supply of cutting tools and no stock-outs.

“Computers are great but when you add the human dimension of proactive customer support, the mix is even more powerful to support our customers,” says Tony.

Ceratizit are so confident that customers will feel the benefits of this service that they never sign a contract tying the customer in. They give 24/7 access to cutting with full control and the stock is consigned so the customer only pays for the tools they use.

The customer never gets left with obsolete cutting tools; if a new coating or grade is launched, the old stock is taken out and the new stock is installed, once proven technically, so the customer is always staying one step ahead with technological developments in cutting tools.

There is only one purchase order and invoice per month, saving time and money, and the replenishment of tools is also managed by the Ceratizit UK & Ireland team.

“This is a free service we offer to our loyal customers; we take care of the tools so they can concentrate on machining,” says Tony.

Sustainability

Ceratizit have a vision to be the leader in sustainability; they take their responsibility for the environment seriously. By 2025, they aim to be the sustainability leader for the hard metals and cutting tool industry. Therefore, they are implementing sustainability measures along the entire value chain.

Ceratizit has an ambitious sustainability mission. A key part of that mission is to reduce the mining of virgin raw materials to less than 5% by 2030.

“Sustainability is front and centre for us. When you think that to make five twenty-millimetre solid carbide tools it takes two metric tonnes of raw material - that’s two builders’ bags of material being taken out of the ground for every five tools, so something must change.

“A significant contribution to the way we can achieve this is through a practical win/win partnership with our vending customers. We are already visiting the customers to replenish the vending machines, so at the same time we collect the used carbide tools and bring them back to Sheffield on a regular monthly visit which is already scheduled, thus adding no extra miles.

“The customers then receive a 10% premium rate on the current scrap rate per kg, hence win/win,” says Tony.

Industry segment focus

Whilst the company foundation started with ‘Fred in a shed’ engineering customers in 1999 and these customers are still supported directly with the same level of importance and service as they ever were and will be going forward.

Ceratizit has made significant strides in recent years focusing with a key account strategy on the larger customers in specific industry segments with best-in-class component and application cutting tool solutions, and this drive to support this key area for their future growth will continue.

“As we drive forward and continue to work with larger customers with best-in-class solutions and dedicated specialist key account and segment teams, we will never forget where we came from and that very first order from the very first customer is still framed and held with pride,” says Tony.

The future

Expansion plans are firmly in place to further grow the business in terms of not only sales figures and market penetration but more importantly customer service.

The next stage of the development will be bringing all its three locations together into one facility in December 2026. This is set to be at a 2,500 square metre building located on Sheffield’s Advanced Manufacturing Park.

“The Advanced Manufacturing Research Centre (AMRC) started as next-door neighbours to us in the unit next to our current HQ in 2001.

“Roll forward to the present day, it is still very important for us to be at the centre of this exciting hub of innovation and development for our industry,” explains Tony.

At this new state-of-the-art facility, Ceratizit UK & Ireland will have a bigger technical centre with more capacity and capability to support their customers with their projects, helping them to optimise their components and applications, to train their own and their customers’ apprentices and staff on cutting tool technology and applications, and to further develop their ‘Made in Sheffield’ bespoke fixture and workholding service.

It will have a permanent ‘MACH’ stand so customers can enjoy the famous Ceratizit MACH experience all-year round. Its entire team will be housed under one roof, and it will incorporate its vending solution stock and high-performance hybrid logistics, to help power future growth and retain its number one position in the UK & Ireland cutting tools market.

Tony concludes: “This new state-of-the-art facility we move to will raise even further the technical offering, service and support that we provide to our customers.

“And it will bring our entire team back together from three sites to one, a team of 70 people continuing to focus daily on our most important topic from 1999 and still the same today and for the future, our customers.”