The company, which is located in Großmehring near Ingolstadt, has been operating under the name Schabmüller Automobiltechnik GmbH (SMI) since 2003. Before this, the company, founded in 1978 by Franz Schabmüller, was active in the field of special vehicle construction. In 1988, the company entered the automotive supply industry. With the machining and assembly of cubic engine and chassis parts, Schabmüller became a service provider for the automotive industry.

Nowadays, with around 150 employees, Schabmüller is a premium supplier, particularly for automobile manufacturers with high production volumes. Schabmüller can include Daimler, Audi/Porsche and Jaguar/Land Rover in its list of references. However, the most important customer is the VW Group, for which SMI has commissioned its largest plant to date for the production of cylinder head covers.

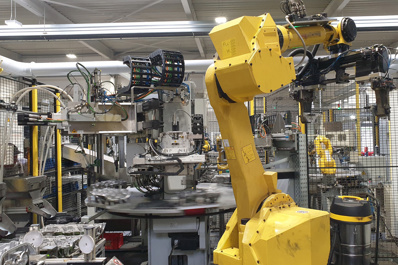

The plant contains 16 machining centres, 26 robots and a number of peripheral machines for downstream machining steps. SMI produces ASM cylinder head covers here for the customer. These consist of a left and right cylinder head cover for the VW 3.0 litre V-group engine, fully assembled with camshaft bearing covers. Over 320,000 sets are produced annually.

SMI operates predominantly as a Tier 2 supplier, machining parts for large foundry companies. In the meantime, an aluminium forge has also joined the list of clients. Managing Ddrector Helmut Häckl sets great store by this expansion: “The forge mainly orders chassis parts from us. This presents an opportunity for us to diversify in that direction.”

Focus on large-scale series necessities organisational adjustments

Before large-scale series production really took off, SMI produced solely with stand-alone machines: One job at a time was processed manually on a machining centre with one worker. When SMI then received an order in 2013 to manufacture bearing frames for the VW Group, which were to be produced in a quantity of 970,000 parts, manufacturing had to be reorganised.

“It was clear to us that the tool volume would no longer be manageable for us if we equipped seven or eight machines for the same order”, Häckl explained. “It would have been difficult for production management to keep an eye on the quality of the tools and to follow their reconditioning in terms of deadlines. The production must go on and not stop because a tool is missing somewhere.”

But that’s exactly what had happened in the past. For example, five drills were used up in one night, and the early shift started the day with one last remaining tool. Nobody understood what happened.

In other areas, a lack of systematic tool withdrawal resulted in the fact that worn tools ended up in the drawer together with new ones, leading to bottlenecks since this had not been recognised in time. Häckl is clear: “Due to this lack of verifiability of tool removals, we kept having huge problems in production.”

Mapal is the sole tool supplier

SMI needed a supplier who would provide, manage and continuously optimise the tools.

“Of course, we have in-depth knowledge of the tool cutting edge. This is important so that the specialists from both companies can discuss the optimal tool design on an equal footing”, said Häckl.

It was obvious that Mapal would be entrusted with the tool management, as the tool manufacturer is an important supplier for Schabmüller’s production, in which many PCD and solid carbide tools are used.

Tool management services are tailored to the needs of the customer. At Schabmüller, the complete package includes tool material requirement planning, tool presetting, dispensing and reconditioning, technical support for series production, tool and cycle time optimisation as well as tool life optimisation.

Tool dispensing is centrally located in the manufacturing area. In addition to a range of horizontal drawer cabinets from the UNIBASE range, Mapal has also installed vertical cabinets at Schabmüller. Their high drawers are particularly suitable for large complete machining tools.

Around 90% of the tools used by SMI are project-related custom tools. “We use these custom tools to achieve the shortest possible cycle times”, explained Michael Stockbauer, application engineer and tool manager at Mapal. “You couldn’t achieve these times with standard tools.”

Together with colleagues, Stockbauer is on site in Großmehring three to four times a week. When a new project is being launched, MAPAL can even be on site every day.

All-round service for the customer

The tool specialists take care of tools that need to be repaired or sent for regrinding. New tools are ordered if necessary. The technicians set complete tools in the immediate vicinity of tool dispensing and store them with the appropriate dimensions so that the worker can take them from the dispensing machine. A separate shelf is used to store worn tools that have reached the end of their tool life.

Matthias Hahn, project manager tool management at Mapal, sees a major advantage for the customer in the tool setting service: “If the workers had to equip and set the tool themselves, they would be busy for about half an hour while the machine is at a stand-still. This adds up very quickly with multiple machines.” Quality is also guaranteed better if the same skilled workers always carry out the setting.

“Due to the good experience, Mapal is regularly one of the first contacts for tool design when new projects come around”, emphasised Häckl. They also appreciate the short response times: “When we send a CAD model to MAPAL, we get word back from Stephan Streck very quickly. If it’s urgent, we already have an indicative price quote or suggestions for possible solutions for critical tools after three to four days.”

As a technical advisor, Streck was already in charge of the introduction of tool management – a familiarity that is also appreciated by the customer.

Everything in view via digital logistics

Schabmüller was one of the first companies to convert its tool data management to c-Com. The software enables end-to-end digital logistics and is connected to the existing SAP system. The large platform makes work easier for all project participants.

For each individual material number, all important data such as reorder points, minimum and maximum stocks and lot sizes are stored here. When a tool is removed from the machine, the stock in the material planning cockpit is updated within seconds. A practical help is being able to visualise the stocks with a traffic light system, where critical values can be detected at a glance.

Since the introduction of tool management, SMI has had an overview of its actual tool consumption. “In the past, we never really knew how high our tool costs were”, said Häckl.

In a joint monthly meeting, SMI and MAPAL analyse what’s been going on in production. The data reveal weak points with tools, but also allow conclusions to be made about problems with the machine or individual spindles. The upcoming quantities are communicated at the meetings so that tool deliveries can be planned in advance.

Processes are improved by working on this closely together. SMI first runs in new tools with the cutting data specified by Mapal, which are then optimised step by step, production manager Albert Neumeier, noted. “If we don’t get anywhere with that, we bring in Mapal. In every project there are tools that are a bit tricky and where you have to adjust the milling strategy a little to get where you want to go.”

Matthias Hahn appreciates this approach: “Schabmüller challenges us and that’s a good thing, because it leads to good results.”

In order to gain even more background knowledge about the tools, a four-day training course was held for three SMI employees at the Mapal Academy in Aalen and Altenstadt. Aside from the knowledge acquired about solid carbide, PCD and fine boring tools as well as cutting edges, the participants praised the high practical relevance of the training units more than anything else. “That’s why we would like to have the training carried out for more employees”, Albert Neumeier continues.

Confirmation by external audit

Like any supplier, SMI has to undergo regular audits. This year, the external partners operating within the company were also audited. Mapal Tool Management received independent confirmation and achieved 98.5 out of 100 possible points right away. The auditors praised the audited processes, saying they were well thought-out and efficient.

Schabmüller continues to grow at a rapid pace. At the moment, preparations for a new project are in full swing. As well as the two existing halls, a third one is being built, where cylinder head covers for a 1.5-litre engine of the VW Group will be exclusively produced from 2025.

The annual volume is over 910,000 units, the investments for machinery and equipment amount to 24.5 million euros. MAPAL will also support this project via tool management with a tool dispensing system. To date, SMI already uses 750 different tools from MAPAL. The new project should add about another 150.