As its existing CNC machinery at the time was not able to produce what was required for the complex jar feed scrolls, it decided first to invest in a DMC DM50V machining centre from Leader CNC (024 7635 3874) fitted with a Samchully fourth axis unit (Thame Workholding, 01844 208050), which workshop manager Neil Hutt says is vital for that particular component.

He says: “Even with the new machine, I was having issues with our CAM software. In particular, the cycle would not flow. I knew how I wanted it to work, but could never achieve it with our CAM system. I had to segment the operation and do it in several stages, when what I really needed was to program it, press go and let it run from start to finish, with confidence. The surface finish wasn’t good, either, with dig-ins.”

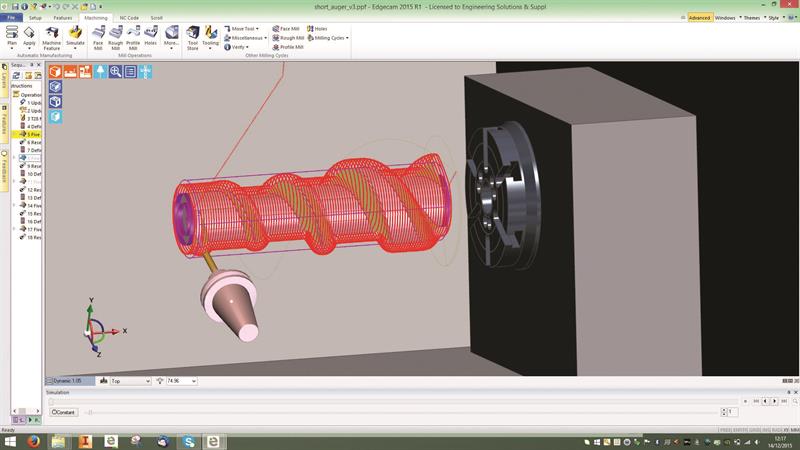

The company observed demonstrations from a number of CAM specialists before choosing Edgecam, from Vero Software (01242 542040). Says Hutt: “Compared to our previous software, Edgecam is more logical, with a user friendly interface. It’s easier to see the way we want to do things and then to carry them out.” Edgecam has also provided a continuous cycle, with the software avoiding the prior dig-ins that marred the components’ surfaces, he reports.

Edgecam programming screen

During the initial training process, Edgecam engineer Dave Currah stored commands for each cycle in separate files. Programming now takes between 30-45 minutes. The size and shape of each jar requires its own set of tooling. “There are approximately 100 different variations of the scroll systems already in operation and we anticipate we’ll need to make a full tooling set, including the associated parts that go with it, every six months.”

Hutt says there are multiple food manufacturers nationally that use the same type of scroll to control the flow of jars, bottles and tubs into a specific part of the machine for filling. Edgecam has now given Engineering Solutions the confidence to tender for the work. He concludes: “We can now provide our own solution to companies for around half the cost charged for this part of the operation by the manufacturer of the overall conveyor system.”

This article was published in the June 2016 issue of Machinery magazine.