The production IT market has arguably been a bit predictable for many years with the big players dominating, but now, SprutCAM, a Cyprus-based software provider has rebranded to Ency Software and has launched a new CAD/CAM/OLP system designed to transform manufacturing processes.

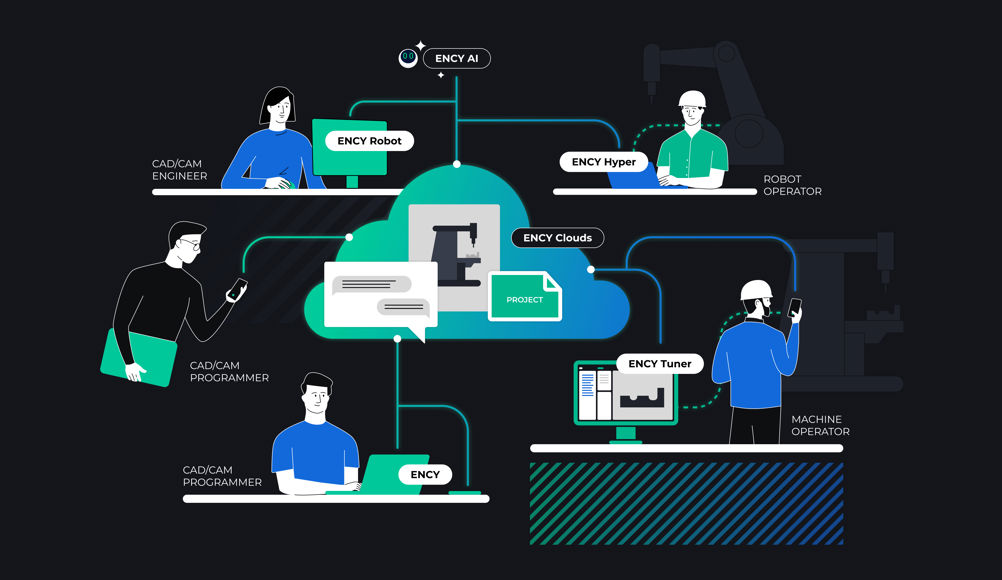

The Ency Software product line that has been launched includes Ency (CAD/CAM), Ency Robot, Ency Tuner and Ency Clouds, and in 2025 it will add Ency Hyper to its portfolio.

Ency Software was previously called SprutCAM, established more than 30 years ago by the father of current chief executive officer Andrei Kharatsidi. He fondly remembers when he was a child and his father was sitting at night after night pouring over tool paths and developing the software.

A driving force behind the rebrand and development was Kharatsidi belief that the market has not evolved in decades with interfaces stuck in the last century, fragmented tools struggling to communicate with one another and no major changes having been made to software in the last five to 10 years.

His belief is that CAD/CAM software no longer meets the demands of modern production with most too focused on the technology, but he is sure that Ency Software will “bring something different” to the market that is currently not available.

PRODUCT INNOVATION

In terms of a more detailed look at the product line rolled out by Ency Software, according to Kharatsidi, the offering is “more than just a range of innovative software products” for automating CNC machine and industrial robot programming.

He believes that operators will gain a unique user experience, as the software facilitates collaboration and data exchange among software providers, robot integrators, programmers, and machine operators on the shop floor.

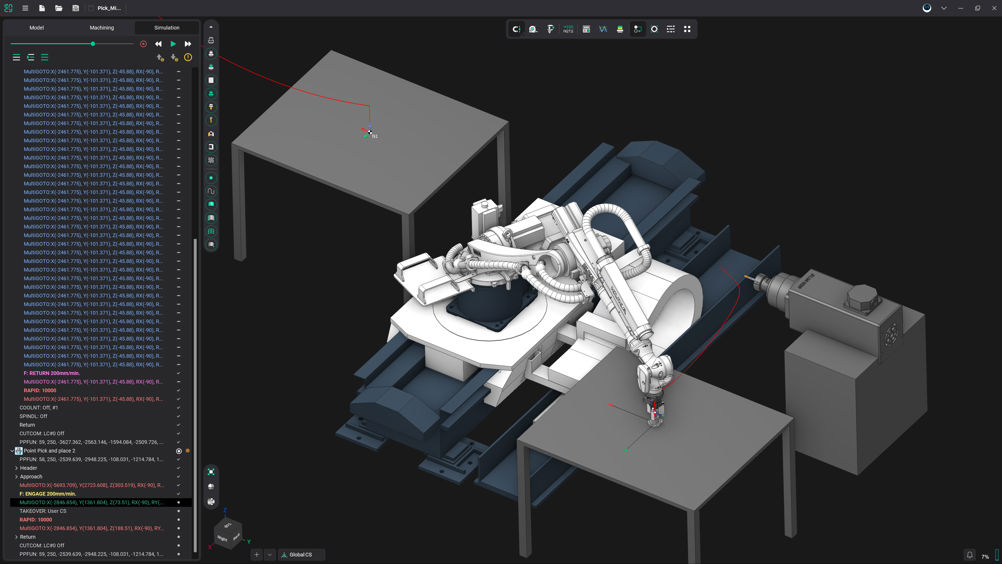

The products include Ency, CAD/CAM software which is designed for a “new generation”, and aims to deliver sophisticated CAM technology with an intuitive user interface and natural workflow.

Then there is Ency Robot, a complete offline robot programming solution with advanced toolpath calculation, kinematics management, and simulation for robots. An all-in-one package featuring design, technology setup, toolpath calculation and simulation.

Another new innovation is Ency Tuner, a shop floor G-code simulator and NC program editor, providing G-code simulation, fine-tuning, and re-engineering for CNC machines and industrial robots.

Kharatsidi explains that users can simply import legacy G-code, simulate, and verify. If needed, they can remove unwanted segments of the legacy G-code and replace them with Ency’s native operations.

Beyond NC-code creation, he says communications and data exchange are the most time-consuming tasks so to solve this, it has developed Ency Clouds, a cloud-based collaboration among CAM programmers, machine operators, and machining project participants.

This tool seamlessly integrates online chat and a project library into the software, meaning no more emails, cloud drives, bloated hard drives, paper, or manually sending photos and videos to troubleshoot issues.

In future, Ency Software will soon add to its armoury with Ency Hyper, a versatile real-time robot programming software that will be launched in 2025, and Ency AI, a next-generation assistant that automates tasks and enriches CAM projects.

By incorporating an AI assistant into the collaboration chat it will boost productivity and as it will know everything about machining and the software.

The AI assistant will collect information about the chat and have knowledge about particular issues, what is discussed, the type of technology, what is being machined, materials, to help solve any challenges.

Kharatsidi believes that with AI assistant in the collaboration chat or in the cloud collaboration platform, there will be someday a possibility to build the Oracle of CNC machining and robot programming so that this AI assistant knows everything about every project which happened over many years.

INTERFACE FOCUS

One area of real focus for Ency Software in its new CAD/CAM/OLP system was the interface, as the company’s developers believe this is something that is not focused on enough by other providers.

“We focused on the interface because very often CAD/CAM software is made by engineers for engineers, and the interface is the last thing they are thinking about,” says Kharatsidi.

“Our idea was that any software must have a good interface. First of all, it will be nice to work with every day because people spend a lot of time in front of the interface, and it is almost everything they see during their job, so we were focused on creating a good interface.

“I am sure we have maybe if not the best, then one of the best interface solutions in this area. We have great simulation, great colours, great workflow, which is all important.”

As part of the overhaul of the interface, it has moved from a white to dark theme, at the request of customers, who often work late at night and asked for this change so they can reduce eye fatigue. This is also aligned with Ency Software’s strategy to be different.

During the life cycle of the company, it has always given high priority to the interface, making it effective in terms of workflow, but at the same time keeping it simple as it believes it is very easy to develop an over-bloated interface with 100 buttons on the screen.

Kharatsidi says: “You can see examples out there, there are plenty of them. There is also a temptation to add a new button or a new checkbox on the screen in the software, because you have hundreds of features and parameters. A lot of things are happening here. And to keep this interface simple is a really, really hard task.

“In our company, this was a priority from the very beginning, and I think we were able to keep it simple. We have a very nice interface which makes daily work, enjoyable.”

He believes it is so important to have software that not only works well but also looks nice, as the Gen Z generation do not want to work with software which looks like Microsoft Office 97, as they have grown up with a smartphone in their hands and are used to good interfaces.

SOLVING THE LEGACY

Many CAD/CAM software systems have been around for many years and Kharatsidi believes that the “legacy” of these systems has hindered their development as it becomes much harder to introduce new developments and changes with the legacy becoming an obstacle.

Completely developing new CAD/CAM software can take five years or so and fraught with difficulties, but Ency Software believes it has overcome this during development to make major changes.

He explains: “There are a lot of rules inside the software, a lot of limitations, and you have to change everything from the foundation, and you cannot do this. Many companies tried to do that and failed.

“I think that we successfully overcame this problem with legacy code. At the right moment, we decided to change the architecture of the software, and this was like a fresh start for us because we started changing something which has not been changed for 20 years in the software.

“All CAD/CAM software developers have the same problems and challenges in front of us. We were able to overcome these challenges as a company and now we have a software product which is developing very fast. We can do a lot of things, a lot of new technology, change the interface, change the workflow, whatever. Change, for example, the tool path calculation.

“Not changing the algorithms, but how the tool path calculation algorithm is utilising the CPU is also important because today it's multi-core CPUs make calculations really fast, but old CAD/CAM software still use one core tool path calculation, which is ridiculous when you have 24 cores in your CPU so we are flexible now.

“We can do a lot of changes and make fast developments. But we asked ourselves, how do we actually make a breakthrough? How do we become a company which is changing the approach or changing the daily life of our customer?”

Kharatsidi notes this led to a vision being created for Ency Software focused on saving time for customers, and providing them with a solution that allows them to seamlessly transition from CAD to finished parts with the fastest turnaround in the industry.

ADDED VALUE

Kharatsidi believes that Ency Software’s new CADM/CAM/OLP system is a completely new value proposition for users and a game-changer for engineers.

“What we are offering is a new CNC machine and robot programming experience driven by high-end CAD CAM OLP software, cloud collaboration, and artificial intelligence. No less than that,” he says.

“We can definitely say that yes, we are different. These are real products, a real product strategy, which is a foundation for a new experience. And we can say that there are zero competitors who are doing the same thing.

“We have created something which puts additional value into CAD/CAM software. And with the tuner, which is not CAD/CAM software, but a shop floor software, we have created an ecosystem for our users.

“This ecosystem is aligned perfectly with our vision, in making a shorter time for transition from CAD to actually finished parts. And we try to do it the shortest time in the industry.”

There will be more development of Ency Software’s system and offerings when Ency Hyper, a versatile real-time robot programming software and more new enhancements and features are set to be added in the future.

Kharatsidi concludes: “I would like to say that our priority and our direction (for the future) is 5-axis machining and additive manufacturing (AM). These are technologies which are developing now and the demand for 5-axis is going up. AM is a complete game-changer for many areas and especially with robots, it is a perfect combination.

“These are high-end CAD/CAM areas where there are not a lot of competition, or relatively little competition, and we can offer a really nice solution in these. Combined with the tuner and the cloud collaboration, we have a very strong value proposition in terms of marketing and the actual value for the end users.

“We can say that we now have a value proposition with a CAD/CAM/OLP ecosystem that is built to transform the way our customers work.”

Visit www.encycam.com for more information.

Andrei Kharatsidi, CEO of Ency Software.