The Oxfordshire-based company is integrating its machine vision technology with Universal Robots’ UR series of cobots that are supplied in the UK by RA Rodriguez (UK). (see Machinery article here for more on cobots.)

Says Earl Yardley, director at IVS: “This new generation of affordable, lightweight robots is unlocking new markets and applications, as they work side by side with human workers. The result is increased total factor productivity and the elimination of the need for costly precision fixtures, thus allowing different parts to be processed and inspected without changing tools.

“We use Rodriguez as they are a qualified, knowledgeable supplier that offers a good background in robotics automation with the UR robots. Working together on projects means we can leverage their substantial knowledge on flexible automation, coupled with our extensive expertise on automated machine vision solutions. As a result, we can approach projects with a team philosophy, utilising a large engineering resource between the two companies.”

One application cited for the vision-enabled UR-series cobots will be in the assistance of human workers for inspection processes. IVS believes that, in the future, inspection benches will include space for an operator and a robot to work in partnership as part of the quality control process.

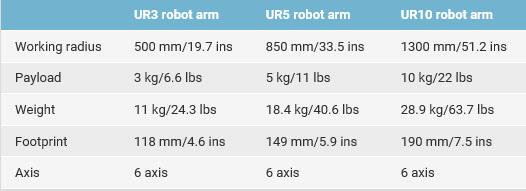

IVS will offer vision-enabled versions of Universal Robots’ UR3, UR5, and UR10 models. The UR3, in particular, is expected to prove popular. This table-top robot can be used to provide camera inspection on multiple sides of complex parts and components, allowing automated inspection.

The compact UR3 weighs 11 kg and has a payload of 3 kg, ±360° rotation on all wrist joints and infinite rotation on the end joint. All three robots feature identical safety systems and ±0.1 mm repeatability. The UR3 has a default force sensing of 150 N but can be set to stop if it encounters a force as low as 50 N.

Below: Table showing UR robot range capacities