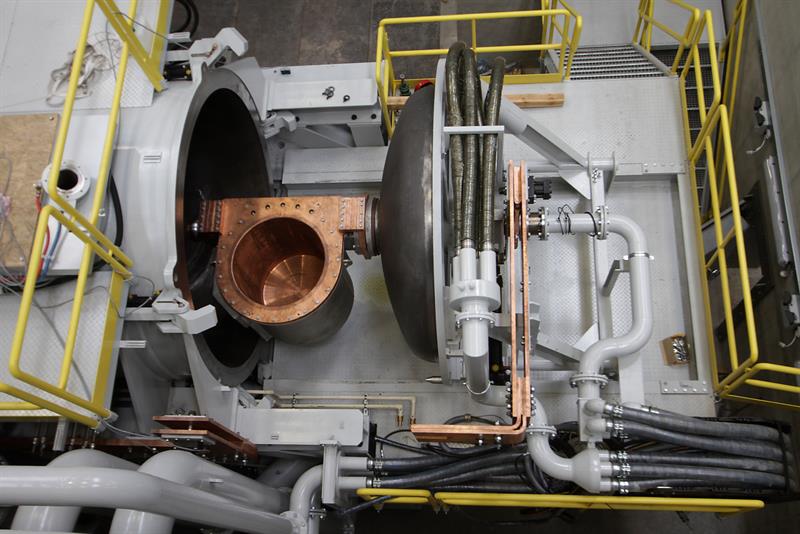

Construction of the furnace for the AMRC Castings Group was completed last year, with the first tests, or ‘hot commissioning’ as it is known, completed successfully in recent weeks. It will be ready for industrial access around summer 2017.

The furnace has three interchangeable crucibles with the capacity for melting 250 kg, 500 kg and 1,000 kg of metal. Able to produce castings from 60 kg up, a molten mass in excess of 1,000 kg is required to make a 500 kg titanium casting. Only a handful of furnaces exist globally that are capable of casting near-net-shape aerospace components of this size.

Only a handful of facilities such as this exist in the world

AMRC Castings says that leading aerospace primes and manufacturing companies are lining up to collaborate on research, but the organisation is conducting initial paper and pilot studies to identify the risks and value streams associated with casting such large-scale near-net shape titanium components.

The research aims to refine and enhance the casting process such that large-scale aerospace components having a lower buy-to-fly ratio can be produced, while also maintaining performance versus forged counterparts.

AMRC Castings' research and development manager, Mark D’Souza-Mathew, says: “AMRC Castings has over 15 years of experience in casting titanium and we are now aiming to assist companies considering a transfer of manufacturing from forged to cast for the production of large-scale near-net shape components.

“The cost savings with near-net shape castings are huge, with efficiencies in wastage and time-savings on the machining and finishing processes. Buy-to-fly ratios are improved from 5:1 with typical forged components down to 1.5:1 via the cast route.”

Casting is now able to produce superior material properties to both forging and machining. In particular, the new furnace built at AMRC Castings’ facility allows enhanced cooling to better control the material microstructure.

Says D’Souza-Mathew: “We are reviewing the alternative manufacturing technologies to focus on our strengths, delivering to the end-users improved part complexity and ‘light-weighting’, realising reductions in manufacturing costs and operational emissions.

“We are working with the Aerospace Technology Institute and the High Value Manufacturing Catapult to define a programme of work and explore the boundaries of large-scale near-net shape castings. This will include retro-fitting the workshop floor with sensors to extract process related information, with a view to developing manufacturing intelligence and supporting simulation software.

“In addition to simulating the melting and pouring stages, we also aim to apply finite element analysis to the shell development stage. The aims are to improve process consistency and achieve manufacturing excellence, providing end-users with an increased level of confidence when manufacturing high integrity parts.”

AMRC Castings’ new furnace is part of a major investment and R&D programme, designed to enable UK companies to break into global markets for large-scale titanium aerospace engine and structural components and is backed by the UK’s Aerospace Technology Institute; innovation agency Innovate UK; and the High Value Manufacturing Catapult.

The wider goal for the AMRC is to establish the UK’s position as a leading supplier of this high value, high impact technology, with dissemination to the participating supply chain strengthening existing operations, developing strong business models for new operations such as volume production foundries and strengthening intellectual property; increasing skill levels and generating jobs within the UK.