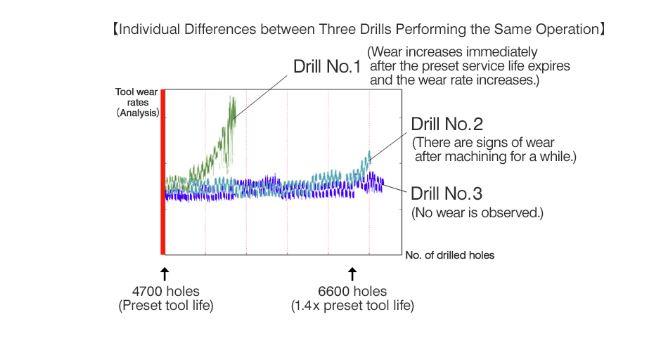

OSP-AI Machining Diagnostics detects drilling abnormalities and provides visualization (graphics) of tool wear from a real time AI system built in the OSP (Okuma Control). The “drilling diagnostics”

This technology prevents drill and/or workpiece damage, makes drill changes when appropriate and so supports drastically reduced tooling costs.

The system has three key elements: drilling abnormalities can be detected early to stop the operation before a tool breaks and retract it to minimise tool or workpiece damage; drill tool wear conditions can be accurately plotted in graphs (claimed as a world first), with drill replacements optimised to drastically reduce tooling costs; Okuma-acquired machining know-how is incorporated into the OSP-AI to eliminate setting each particular cutting condition by simply using the AI drilling diagnostics function.