Machine tool controls have a new look. In DMG Mori's CELOS, Mazak's Smooth Technology, Okuma's OSP Suite and Siemens's Sinumerik Operate (planned for launch at the EMO exhibition in October), G-code readouts have been banished to sub-menus and replaced by a new dashboard-type interface on a simple – and stylish – background. In their smartphone aesthetic, displays are not only touch-sensitive but respond to screen gestures; they are dotted with icons that call up sub-screens; they summarise job information speedometer-style.

These new views mostly sit on top of traditional CNCs and offer a new way to interact with the machine, even as the original CNC interface remains intact – and accessible – within. Their job is to simplify and speed up various routine operations. They aim to appeal to younger users, who are likely to have little machine tool experience but plenty of hours logged on tablet computers and smartphones. They have not been rolled out across entire machine ranges – partly because they are new, and partly because they are a premium feature and, as such, restricted to generally high-end machines.

Apart from a flashy new design, these interfaces share several other features of tablets and smartphones. First, the new-look controls assume that the machine will connect to the company network at least, if not the internet and the cloud beyond, using Ethernet. Connectivity enables these systems to share machine jobs with each other and the office, provide machine status visibility and receive CAD files and other supporting documents. This capability is perfect for production environments where long-run jobs are programmed offline, with data then sent to a machine. Some systems have associated smartphone apps to provide machine status updates out of the office. Others feed production information back into ERP systems.

The second similarity to smartphones is graphics capability; with their enlargened visual display screens, operators can see more than ever before. For example, they can view CAD files on the machine (Okuma OSP Suite loads and runs CADCAM software on its Windows 7 operating system; CELOS opens a view to a networked desktop computer running CADCAM; Okuma's OSP Suite has an icon link to PC-DMIS NC Gage from Hexagon Metrology, 01952 681300). New document viewing software allows operators to consult a digital machine manual when an error message pops up, or other job information, or notes left by another shift operator.

The third similarity with tablets and smartphones is that the new interfaces are one-size-fits-all; they are flexible enough to cater for a wide range of interests. Mazak says that one of the goals of Smooth Technology is to consolidate specialist machining operations on to one platform. Likewise, DMG Mori and Siemens admit that part of the reason for launching these new interfaces is to standardise the design of controls for turning and milling machines to create one single standard look and feel. In the case of DMG Mori, this difference, caused by a historical legacy, actually spans different control suppliers: MAPPS 5 with Mitsubishi or Fanuc for Japanese-made machines, and Siemens or Heidenhain for German-made ones. (Fanuc declined to comment for this article; and Heidenhain, which did, is not working with DMG Mori on CELOS).

DMG Mori CELOS

Taking the controls in turn and in more detail, the DMG Mori (0247 651 6120) system was shipped with about 375 machines worldwide in 2014; for this year the target is more than 10 times as many. CELOS ships with NLX lathes, NTX turn-mills, NVX vertical and NHX horizontal machining centres.

Its interface is modular: screens are organised into colour-coded 'apps' (production; utilities; support; configuration; views and diagnostics). Four new ones were launched last month – job scheduler; messenger; service agent; and tool handling – and more are promised for the future.

A version of CELOS is now available to install on a desktop PC. This can monitor the status of all networked machines (including non-DMG Mori machines, although with a reduced level of information) and monitor the status of jobs currently underway.

CELOS's multiple access levels allow greater control over the manufacturing process. In an industry presentation in March at DMG Mori, Coventry, training manager Markus Kissinger explained that 80% of an operator's adjustments to a job will not reach the job designer; this process risks losing vital knowledge about how to do the job accurately. In CELOS, the operator is not allowed to change the job; if there is a problem, he or she must talk to the job designer. Says Kissinger: "We are creating a new workflow to get the feedback." Moreover, before they are able to start a job, operators must first sign off its tooling and workholding. As well as providing a check on the job designer's work, this structure creates a chain of command; operators can't plead ignorance when the wrong vice jaws are chosen and the workpiece damaged, for example.

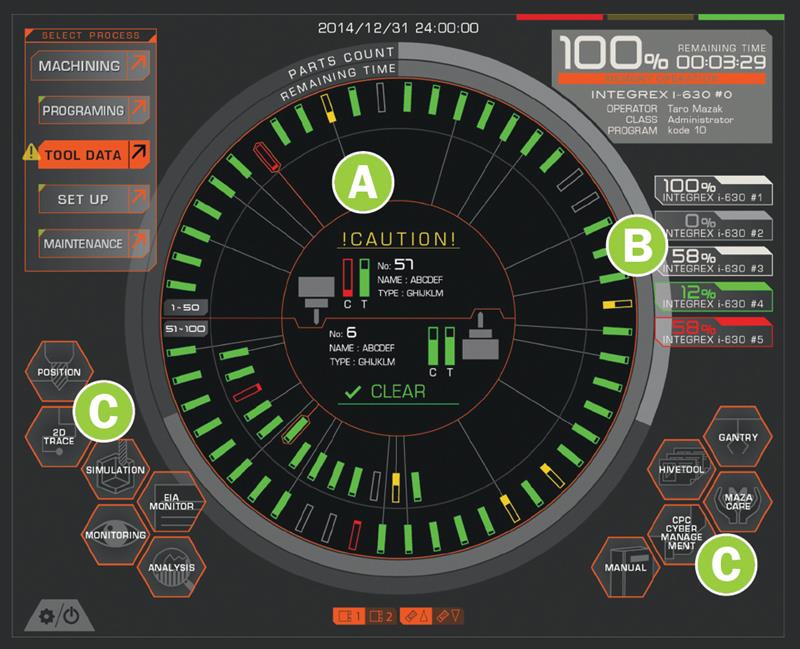

A: Error screen: the current tool, ringed in red, has nearly exceeded its expected life (its 'life' box is nearly empty). Tools are also colour coded by remaining life. B: Status monitoring of up to five machines is standard. C: Links to tools and help, including: position, 2D trace, simulation, analysis, manual, more

Mazak Smooth Technology

Mazak's (01905 755 755) new control developments, due to launch in Europe this month at an Open House, 13-15 May, was first shown on Variaxis and Integrex machines at exhibitions last year in Japan (JIMTOF) and the US (IMTS).

Smooth Technology includes several different technologies. The new Smooth graphical user interface has the biggest visual impact: it incorporates five new home screens: machining, programming, tooling, set-up and maintenance, all with quite a radical design and displayed on a new 19 inch touch-screen display unit that, for the first time, is tiltable, so it can adapt to the height of operators large and small.

To take just one feature out of many, the new Smooth Machining Configurator helps operators fine-tune machine performance where freeform surfaces are involved. The screen presents users with machine controls shown as three moveable sliders, like a graphic equaliser on a sound system, that alter parameters affecting component smoothness, accuracy and cut time. Settings can be saved as profiles.

Sitting behind these is a new version of the Mazatrol CNC with supporting hardware and servo innovations.

Okuma OSP Suite

OSP Suite from Okuma (sold through NCMT, 024 7651 6600) was introduced last year only on controls with a 19 inch screen, with these fitted to the MU series of 5-axis machines and Multus mill-turn machines.

Says NCMT pre-sales engineering manager Richard Turner: "With this software, you combine everything in the machine. Within the OSP suite, you have a shortcut to our CADCAM system, where you can do programming. You can check the simulation for the risk of collision. There is a link to a user knowhow database for finding cutting speeds. And it also helps the management of machining: of tooling, the tooling library, and you can keep that information on the machine. Machine maintenance is also all done on the control, in OSP Suite."

OSP Suite consists of about a half-dozen small displays that fit, in adjustable configurations, above and to the side of the P300 control main display. A simple and uncluttered home screen leads to a number of other detailed screens, including notes, setup, cycle time monitor, load metre, load metre trend lines, and work counters. All of these displays can be moved around; changes being saved in one of three different user profiles.

So far, Bromford Industries of Birmingham (0121 683 6200) is the only UK customer running OSP Suite, on an Okuma VMC (a MU6300V-L); two more are also on order.

Siemens Sinumerik Operate control on touchscreen displays with and without a keypad

Siemens Sinumerik Operate control on touchscreen displays with and without a keypad

Siemens Sinumerik OPERATE

Machinery was given an early look at Siemens's (0112 385 2500) new software, which is not due to launch until EMO in October. Until then, only a dozen pilot users worldwide are testing the system.

Andrew Hodgson, general manager – motion control, Digital Factory, Siemens UK & Ireland, says: "There is a new philosophy in this software. There are many new features to assist the end user and operator, in line with the CELOS and SmoothX sort of technologies, to provide them with more usability and performance. The big OEMs can do this for their own equipment, but lots of smaller companies can't. So Siemens is helping them by keeping up with the technology."

Developments are based on new CNC hardware that is faster and more powerful than before.

Siemens's touchscreen-based system, available only on the 840D control, now supports pinching and squeezing to zoom in or out on a 3D simulation. "Siemens wanted to develop a more meaningful, interactive approach to tablet technology. We didn't want to just go ahead and have it as a fashion statement," Hodgson explains.

Four new packages are available to manage the machine on the shopfloor. smartPrepare is an offline programming system that sets up jobs using the same software as runs on the machine. A virtual NC kernel takes the parameters of the actual machine and connects to the tool store to estimate tool wear, simulating this based on machine-specific data. smartOperate enables actions to be carried out on the touch-screen, optimised in such a way that, for example, pinching one part of the screen doesn't expand the whole screen. smartIT indicates performance trends, and links to job information held on networked office PCs. Finally, smartMobile enables remote users to monitor the machine from a phone.