Amada (01562 749500) – ACIES-AJ combination laser/punch has a servo-electric drive, 30 tonne punching capacity and either 2 or 4 kW fibre laser. Working range for the new machine is 3,000 by 1,500 mm. A 32-station turret is backed up by 300-tool storage and automation of sheet and part handling, as well as automatic laser nozzle change support unmanned running capability. LCG-3015AJ flatbed laser profilers (video: https://is.gd/pifeka) with a working range of 3,000 by 1,500 mm boast Amada-developed 6 and 9 kW fibre laser sources. They operate at a positioning speed of 170 m/s. The ENSIS-3015AJ laser profiler range has been expanded with the addition of a 3 kW fibre laser source. It has a working range of 3,000 by 1,500 mm and positioning speed of 170 m/s. Fibre laser welding robot FLW-ENSIS now has a 3 kW fibre laser that enables deeper penetration welds than the existing 4 kW fibre laser, plus has a new filler wire system. More productive yet still safe bending is a further Amada development, via Finger with Active Security Technology (FAST) – new stop fingers have an active safety device that limits risk to operators, if they come into contact with moving parts. Time savings of around 12% for the production of a part having seven folds are claimed on a ‘fast’ machine, with a 36% time-saving compared to another commercially available model processing a comparable part. It was fitted to one of its HFE 3i 1003 pressbrakes, as was Amada’s HG-ATC auto tool loading, for which time savings of more than 50%, and even 80%, are claimed. New pressbrake unloading module AC300 was also shown. New VPSS 3i software (video: https://is.gd/oxonif) allows unified programming and simulation of all Amada technologies (blank, bend and weld). It is part of Amada’s wider approach to Smart Manufacturing: V-factory.

AP&T of Sweden (http://aptgroup.com) – SpeedFeeder handling robot is for press lines; acceleration is approximately 20% faster than the previous model, while it is 10% more energy efficient, although compared to conventional industrial robots, the difference can be as much as 50%.

Bruderer (01582 560300) – A new way of experiencing high speed press technology was demonstrated, with visitors transported into a virtual world. Using 3D headsets and representations of a BSTA 510-150 with B2 control and BSV 170 servo feed unit, wearers gained an insight into the technology that goes into building the presses and how they operate in a workshop environment.

Haco (Kingsland, 0121 522 4929) – Two fibre laser profilers, FL 3015 LU (3 by 1.5 m in X) and FL 4015 LU (4 by 1.5 m in X), can each have either a 3 or 4 kW laser. A key feature is the laser head, which uses parallel kinematics to achieve acceleration of 5G (video: https://is.gd/newohi). Of improved design, Pressmaster 36150 pressbrake is a 5-axis, 150 ton, 3,655 mm bending length unit that offers Haco CNC with 2D/3D graphics and automatic bending program generation, Haco’s backgauge system, plus both increased daylight opening (490 mm) and stroke (370 mm). Wila hydraulic upper tool clamping and hydraulic crowning table feature.

Hexagon (01952 681300) – Tube, wire and spring bending software BendingStudio version 3.1 from Aicon boasts better user friendliness, particularly ‘Assembly’ that checks holders and extensions.

Jetcam (0845 2996035) – Line Commander provides complete automation via drag-and-drop scheduling for laser profilers that sees material loaded from the stocker into the laser table, downloading CNC programs and unloading the cut parts.

KMT (01384 408892) – Waterjet pump Streamline PRO-III delivers up to 6,200 bar. With the unit’s seal having a guaranteed service life of 500 hours, the 93 kW pump offers a combination of motor power and water pressure that supports the fastest cutting speeds in the industry.

LVD (01295 676800) – Synchro-Form is described as “the next leap in adaptive bending technology”. It automatically maintains angular consistency and the required geometric profile when handling, positioning and bending large parts having multiple bends. The system overcomes the problems of accumulative error and trial-and-error bending when forming large profiles. It uses a laser scanner and synchro modules (X-, R-, A-axis magnets) to manipulate, position and measure each bend, relaying the information to the Touch-B control where adjustments to part and ram position are made to achieve the correct profile. Variations are not accumulated but, instead, compensated at each bend step.

Nidec Minster (07885 292197) – Minster EV press range for the production of 0.2 mm thick electric motor laminations is offered in both 250 and 350 ton models, both with 3,700 mm bed lengths.

Roemheld (01462 459052) – A new grip rail coupling that employs the press transfer rail to achieve coupling and uncoupling, avoiding the need for external hydraulic, electric or pneumatic power, won the show prize in the ‘automation & handling’ category.

SafanDarley (0116 200 1777) – E-Brake 200T 4100 ATC is a 200-ton, 4,100 mm bending length servo-electric pressbrake that boasts an automatic toolchanger integrated into the machine frame. The machine and toolchanger can be programmed in the SafanDarley E control or via external systems. Manual loading of tools is still possible and, if the Wila TIPS option is fitted, the toolchange robot can recognise manually-placed tools and put those into the magazine – a claimed unique feature resulting in better efficiency. E-Brake Ultra has a new design and is equipped with CNC crowning. It is available in these sizes: 50 ton by 2 m; 80 ton by 2.5 m: 100 ton by 3 m; and 130 ton by 3 or 4 m. H-Brake Hybrid pressbrakes boast hydraulic/electronic drive that delivers huge energy savings, low noise levels and lower oil use. Models are 110 ton by 3 m and 170 ton by 3, 3.7 and 4 m. Q-dimension is 655 mm; stroke 280 mm; standard gap is 510 mm.

Nearly as simple to operate as a printer: Trumpf’s new profiler and panel bender

Trumpf (01582 725335) – Entry-level TruPunch 1000 is a punch press that can expanded through the addition of a 3 kW fibre laser to become a combination machine, the ‘TruMatic 1000 fiber’. It can handle sheets up to 6.4 mm thick at rates of up to 600 strokes a minute on a footprint of just 6.5 by 4.9 m. Automatic sorting of finished parts measuring up to 180 by 180 mm is possible for both the TruPunch 1000 and the TruMatic 1000 fiber, with parts sent down a chute into up to four different 400 by 300 mm boxes. Both also can be fitted with the new SheetMaster Compact sheet loader. For panel bending, the 220 mm bend length capacity TruBend Center 7030 offers automatic processing by addition of a manipulator that secures the sheet and rotates it as needed. This offers better productivity than the semi-automatic TruBend Center 5030 panel bender. TruBend Center 7030 tackles sheets of aluminium up to

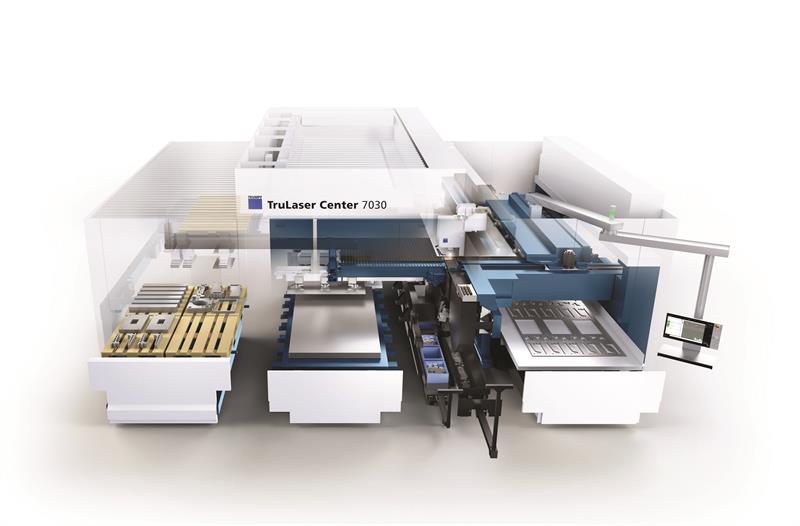

4 mm thick, mild steel up to 3 mm thick or stainless steel up to 2.2 mm thick. Short side lengths, boxes up to 220 mm deep, small profiles, narrow or negative bends and diverse radii are accommodated. The machine is complemented by Trumpf programming software TecZone Fold. Also new, Central Link is part of Trumpf’s Industry 4.0 offer TruConnect. This provides the connection to a company’s machines, ERP systems and also to cloud-hosted services, such as Trumpf’s Axoom. It also connects to Performance Cockpit, a new, web-based solution that provides real-time information on connected devices’ status via PC, tablet or smartphone. The 6 kW, 3 by 1.5 m capacity TruLaser Center 7030 is a new, automated compact machine concept that promises “unmatched efficiency and process reliability in the manufacture of laser-cut parts”. Automated production is supported, with Trumpf saying: “TruLaser Center 7030 operates almost as simply as a printer in an office. If you send it a document with corresponding job data – geometries, amounts, material types, thicknesses – it provides you with the finished parts, sorted and stacked to suit the order. This includes nesting of the parts on the sheet, assignment of cutting technologies, removal strategies, placement of cut parts onto the storage shelves, and ejection into the container.”

Wila (Mate Tooling Solutions, 0800 413408) – Wila Tool Advisor app for iPad and Android helps end users solve bending needs.

Yamazaki Mazak (01905 755755) – New Super Turbo-X 3015 Fiber series is available in both 2 and 3 kW versions and boasts “best-in-class” floorspace of 2.9 by 7.4 m; it can be fitted with Mazak’s existing FMS laser automation systems. Mazak also introduced two new automation systems – Quick Cell, designed by Japanese industrial designer Ken Okuyama, is available in three different specifications, six-stocker, 10-stocker and 14-stocker versions; and LaserFlex 2.0, a compact, easy-to-use solution that enables the fast handling of raw plates. Also new is laser CNC Mazatrol PreviewG, “the world’s fastest CNC”.

This article was first published in the December 2016 issue of Machinery magazine.