Cloud computing – it's probably something many are already using in their personal lives, courtesy of Google or Microsoft. The storage of data or the use of online-hosted software applications are two common services. But now cloud services are linked with NC programming and the provision of cutting tool data, too.

Machinery first encountered such cloud-speak in this sector earlier this year, at an event to highlight Autodesk's (01252 456600) purchase of Birmingham-based CADCAM specialist Delcam. Autodesk's Buzz Kross, senior vice president design lifecycle and simulation, said this of its cloud services, which incorporated its cloud-hosted CAM 360 NC programming software: "We see the cloud as being the same sort of shift that got Autodesk started. The move from Unix to PC marked a big shift and let us jump ahead of the market. The cloud offers amazing value for customers, since they don't have to download or install software, while their data follows them anywhere in the world. We think it is the next revolution coming to engineering."

A video on YouTube posted in February this year (

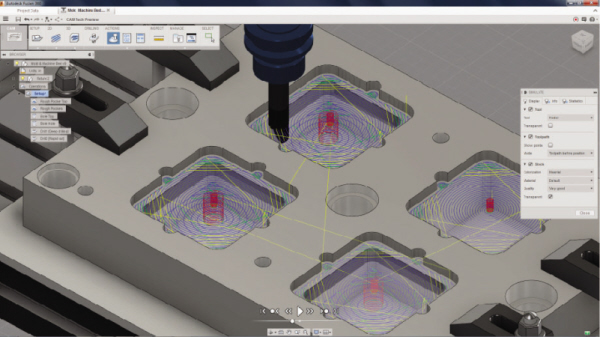

http://is.gd/DbKyhf) heralds CAM 360 as "the First CAM in the Cloud", in fact. This solution is developed around the same CAM kernel as Autodesk's HSMWorks and Inventor HSM, and was launched at the end of last year in 2½D format.

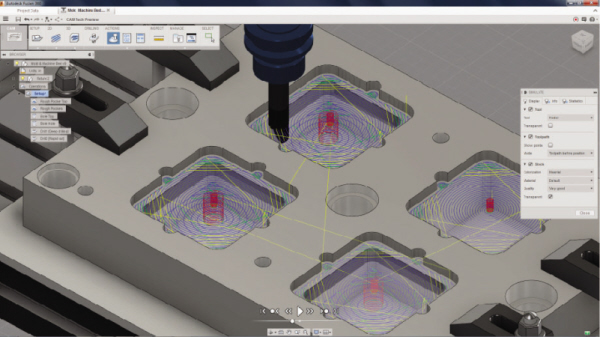

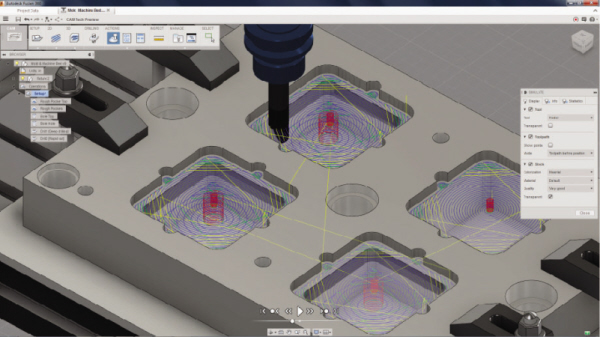

Autodesk's Fusion offering incorporates CAM

Autodesk's Fusion offering incorporates CAM

Following this event, the product has since had a name change to 'CAM for Fusion 360', with this Fusion product encompassing more than toolpath creation. Says Autodesk: "[CAM for Fusion 360 is] the only CAM solution that combines CNC programming, simulation and design, with real-time collaboration and online project and data management, into one easy-to-use product." Fusion predated the CAM 360 launch, officially available on 25 June last year (video:

http://is.gd/Vu4JPw).

CONSISTENT EXPERIENCE

Carl White, US-based senior director manufacturing engineering at Autodesk, confirms that CAM 360 was originally offered stand-alone, but is now part of the Fusion 360 offer, a subscription-based cloud service. There are two levels, $25 or $100/month, the difference on the CAM side being that you get 3D CAM versus 2½D CAM for your $100/month. The standalone offer "broke the workflow experience", explains White, adding: "We have built a consistent experience within the Fusion environment; there's no reason to have a bunch of separate products. All subscribers to Fusion now get this CAM capability, with the workflow really tightly coupled all the way through the process."

Fusion (Windows and Mac) is available globally and does have UK users. Narrowing down to users of the CAM element, White puts this at around 1,000, with some 20% of those doing so via a Mac, although Fusion is free to students and hobbyists, and they are in that total, too. Numbers for the UK are not revealed, nor for any territory, in fact.

CAM for Fusion 360 is currently in beta, but will pass through that later this year, he confirms. That being so, there is no heavy promotion at the moment, but, says White: "This is a really interesting space for the CAM market, which is traditionally a conservative one. You have to do a lot to dislodge existing players, but what is interesting about what we are doing with Fusion is that it is not just drawing, 3D modelling and CAM, but includes a whole ecosystem around it that supports collaboration and file management. That is the more critical part of what we are doing; it's built-in PDM, built-in management of NC files, all of this in the cloud, with access from any machine, and supporting collaboration with anybody around the globe, tracking who did what and allowing the sending of notes to each other.

"It is more than just design or toolpath generation, and that's unique. In a lot of start-ups and small machine shops, this gives the opportunity for the first robust system for them, from the time something comes in or when it is designed, to understand and keep track of everything in one place, all the way through the process."

Next to catch Machinery's eye was DP Technology's Esprit CAM package (CAM Supplies & Services, 0871 218 3001). Just ahead of the UK's MACH exhibition held earlier this year came the announcement of its 'Cloud-enabled CAM'. This is not cloud-based CAM, but cloud-supported CAM, specifically as regards availability of tooling data. Says the company: "With the Esprit 'MachiningCloud Connection', programmers have access to complete and up-to-date tooling product data, which cuts hours of programming time by eliminating the need for manual tool creation.

"Cloud-enabled Esprit also offers a list of recommended cutting tools, based on machining features and machining sequences, and simulates with more accurate 3D models of tool components and assemblies."

In fact, this tool data element behind Esprit's development is delivered by Switzerland-located company Machining Cloud GmbH, previously known as DP Technology Switzerland GmbH – the name was changed in August last year. Further, DP Technology, Camarillo, USA, holds the total share capital of Machining Cloud GmbH.

Since the DP Technology/Esprit announcement, there has ensued a veritable flurry of other moves in similar vein, mostly from cutting tool companies, all with Machining Cloud GmbH as the common element.

TOOLING COMPANIES LINE UP

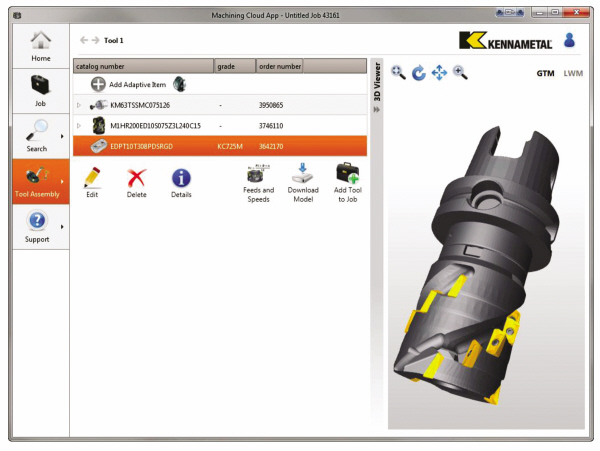

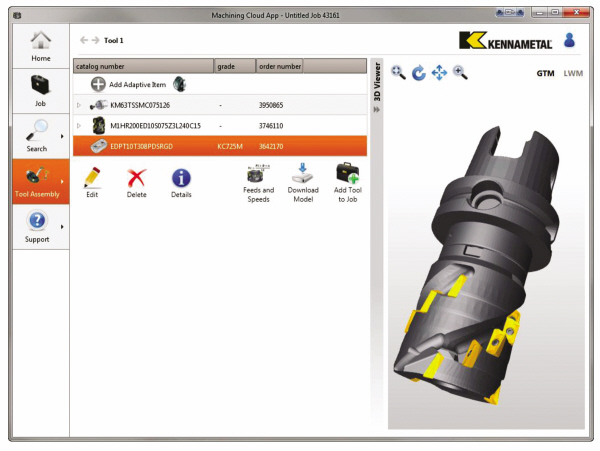

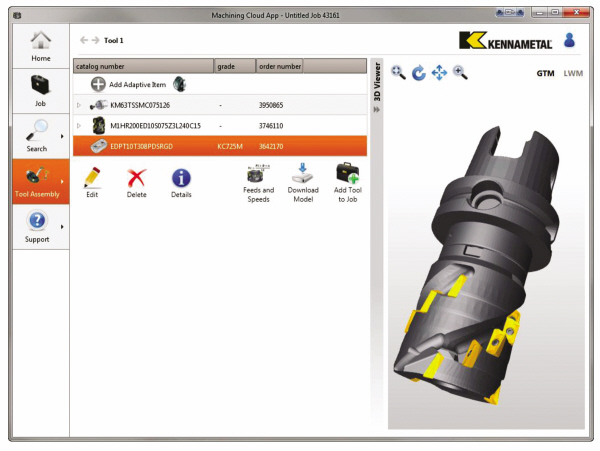

First in this group, was Kennametal, with the introduction of its 'NOVO digital tool', which is supported by Machining Cloud GmbH technology. This actually popped up with less fanfare late last year, but got an extra push in June. And in a reciprocal and clearly necessary move, DP Technology said Esprit is "the first CAM solution to offer a connection to NOVO for automatic and intelligent tool selection".

Since its launch in 2013, Kennametal's NOVO digital tool and process planning application has been expanded, with this latest version now "connecting via the cloud to tool management, e-commerce and other shop systems, reducing data errors and making non-value-added data-transfer efforts things of the past".

Kennametal's NOVO has wider scope than just a tool library

Kennametal's NOVO has wider scope than just a tool library

Says John Jacko, vice president and chief marketing officer at Kennametal: "Our vision for NOVO from the beginning is to provide an open-source system that interacts seamlessly with shop systems needing to leverage cutting tool data and machining knowledge for productivity improvement. This is only the beginning of delivering the promise of the digital factory. Connecting to Kennametal's ToolBOSS tool management system via the cloud and streamlining input into Kennametal's e-commerce system, that vision is quickly becoming reality." Clearly, Kennametal has expansionary cloud service ambitions.

Speaking for Esprit, a Europe-based spokesman for DP Technology highlights the advantages of the cloud connection from its users' perspective: "It's really a big benefit for our customers machining with Kennametal, P Horn, Iscar and Widia tools [who have all adopted Machining Cloud].

"They save hours and hours in ordering tools and, from the CAM side, they just have to hit one button to import their tools into Esprit, with real rendering during simulation, real dimensions, and correct feeds and speeds."

Mastercam author CNC Software Inc (UK agent 4D Engineering, 01285 650111) is another CADCAM company that has linked up with Machining Cloud, as is German company Pimpel GmbH, which is the publisher of CHECKitB4 CNC set-up, verification and simulation software (

http://is.gd/dP4hvM and YouTube video

http://is.gd/oZEgqj). CGTech (01273 773538), publisher of Vericut CNC program simulation software, is another fan on the toolpath generation/verification wing of users. Tool management software firms WinTool and TDM Systems, both of Germany, are other Machining Cloud partners, as is German tool presetting equipment maker Zoller (01283 585933), while Japanese machine tool maker Okuma has also joined the growing throng.

Speaking for CGTech, product marketing manager Bill Hasenjaeger underlines user benefits: "Simulation speed is very important to our customers, but so is the amount of time spent preparing a simulation and its accurate representation of the physical process.

"By collaborating with Machining Cloud partners, Vericut will be able to intelligently and automatically create accurate tools for machining simulation – identifying the cutting and non-cutting portions of the tool assembly, as well as tool mounting locations and driven points."

ECOSYSTEM BUILDING

The appearance is that there is a complete ecosystem being established around Machining Cloud GmbH's technology that connects CADCAM, tooling, tool management, tool presetting and machine tool elements. Indeed, Machining Cloud explains its rationale thus: "Machining Cloud's mission is to provide the manufacturing community a single-source of access to product data from the leading manufacturers of cutting tools, machine tools and workholding that is complete and always up to date."

But the DP Technology connection with Machining Cloud GmbH might give other CADCAM companies cold feet. Certainly Autodesk, for one, is treading its own path in this area, bringing tooling libraries into its Fusion fold independently.

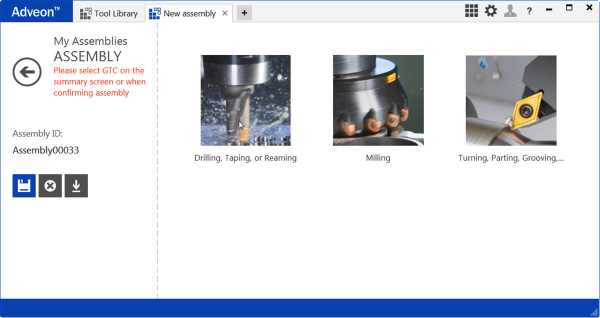

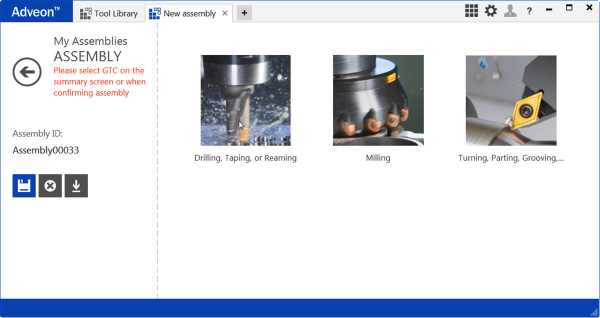

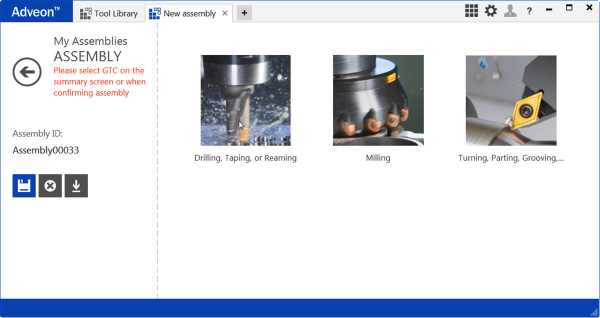

Of course, tooling company Sandvik Coromant had already launched its own open tool database for use with CADCAM systems, Adveon (see Machinery article on ISO 13399 here,

http://is.gd/PC3gnL), with companies such as Edgecam (01242 542040), TopSolid (MCL CADCAM, 01484 866311) and GibbsCAM (Tech CADCAM, 01284 754781) snapping it up.

Sandvik Coromant's Adveon was first, but has Machining Cloud GmbH stolen a march?

Sandvik Coromant's Adveon was first, but has Machining Cloud GmbH stolen a march?

An open system that will accept any company's tool data in ISO 13399 format (the standard adopted by Machining Cloud, too), Adveon can deliver cloud-connected data to CADCAM users, but runs locally after tool data has been downloaded (possible also via DVD/USB), offering users the ability to locally select and 'assemble' tooling, and then make use of solid model assemblies in their systems. So, choose data from the cloud, but run an application locally once data is downloaded, apparently giving the best of both worlds. Machining Cloud seems to require permanent cloud connection to choose and assemble tooling models prior to download, but it does boast a wider catchment of data type than Adveon.

Edgecam has customers running Adveon as beta sites already, and the company's general manager, Raf Lobato, says of cloud-hosted services that, globally, he sees internet connectivity being locked down by companies, as suggested by the lower-than-expected take-up of its online software licence update facility. "We are not seeing the expansion we would have expected to see; more people are locking their PCs down, globally." But that is probably a short-term problem, he admits. That said, in countries such as India, Internet connection is not always reliable, he adds.

Similarly, with cloud-hosted CADCAM software, he offers: "People's trust, as regards security, has been knocked, following the Edward Snowden/NSA revelations, for example. Defence and F1 companies don't want to trust data to the cloud." But he again suggests this reticence will ultimately pass. Edgecam, he reveals, is developing its own solution, in order to offer cloud capability, but in a private and secure manner.

The cloud bandwagon, as it relates to CADCAM and associated activities, has clearly started to roll.

Extended version from here

EU cloud-based engineering services project

Late last year, CAM software TopSolid (MCL CADCAM, 01484 866311) highlighted that it was taking part in EU project CloudFlow, an ongoing collaborative project funded under the 7th Framework Programme of the European Commission (

http://eu-cloudflow.eu). Another partner in the project is University of Nottingham.

Part of the vision for the project says "The new engineers' workplaces do not need to be equipped with expensive software (CAD, CAM, CAE, PLM, data archival) and their required operating systems and versions, or with special hardware (CPU, RAM, GPU) and their dedicated drivers. Therefore, the engineer will not need multiple computers for different tasks; or in the case of limited computers, the engineers will not need to wait for the availability of the resources."

It has the ambition "to provide a Cloud Computing infrastructure based on existing technology and standards that allows SME software vendors to offer current and future customers new cloud services along and across the engineering and manufacturing chain - even vendor independent."

US-side cloud developments: a foretaste of what's to come?

Japanese CNC and automation technology specialist Mitsubishi Electric Automation's offers a cloud-hosted CNC data back-up service, designed to help manufacturer's reduce downtime and prevent service calls. Launched into the US market at the end of last year, the service includes the creation and maintenance of a "comprehensive set of backups of a manufacturer's CNC machine tool data, stored in a secure, remote location that can be accessed 24/7." The US price is given as $125.00 per backup, per machine. There is no equivalent UK service, Machinery was told.

Machine tool maker Okuma has also made an announcement, partnering with the ubiquitous Machining Cloud GmbH. Okuma says that user-friendly PC and tablet apps simplify the process of finding the right machines and cutting tools for any given manufacturing job.

With a dynamic 3D tool assembly configurator, the apps can download digital machine models with their kinematics and complete cutting tool assemblies into CAM, CAD, tool pre-setting and tool-inventory software.

The Machining Cloud App for Okuma will be released later this year in the US. Planned to be available for Microsoft Windows 7 and 8, as well as Windows tablets, Android tablets and the iPad, launch of this technology in the UK is as yet an unknown.