The XYZ LR range is intended as the first step to VMC ownership, while still offering “exceptional specification and performance”. The move into linear rail ball bearing slideways complements the existing box slideway machines offered by the company and is prompted by advances in the technology.

Explains Nigel Atherton, managing director, XYZ Machine Tools: “While the use of linear rails has been common for many years, here at XYZ we have resisted their introduction as we felt that the technology, up until now, did not meet our stringent performance criteria, in the same way that box slideways do. However, with recent advances in linear rail design, those concerns have been laid to rest and these machines will allow users to maximise the improvements in digital motion control and modern cutting tool technology, while providing a cost advantage to customers by helping them to migrate to CNC machining centre ownership at reduced cost.”

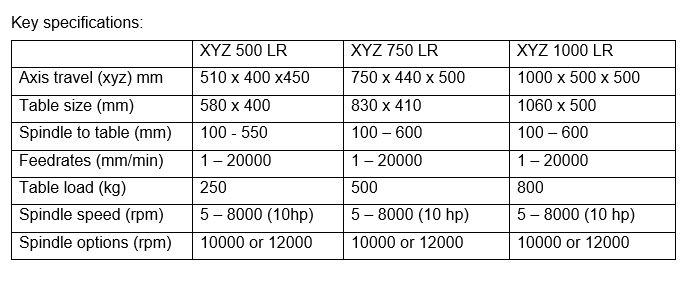

The three-machine range comprises the XYZ 500 LR, XYZ 750 LR and XYZ 1000 LR (the nomenclature relating to X-axis travel). Siemens 828D control, with the option of the ShopMill Advanced software package, is offered, with a standard 8,000 rpm spindle and options of 10,000 or 12,000 rpm. Other generic specifications include feedrates of up to 20 m/min in all axes and 12- or 20-position carousel toolchange as standard, dependent on machine size, with the option of a 24-position arm-type on the two larger machines. Table capacity is 250 kg, 500 kg and 800 kg, respectively.

“At XYZ, we are constantly looking to maximise the performance and productivity of our customers, and the XYZ LR range is just the latest step along that path. Combined with the recent introduction of the XYZ UMC-5X, gantry-type, 5-axis machine, along with other developments to follow later in 2017, we will continue to provide the machines that allow our customers to grow and develop their businesses,” says Atherton.