Armroid made its appearance at the recent JIMTOF exhibition in Tokyo and not only offers automated load/unload in conjunction with a separate unit that can be wheeled into place, but also can provide a steadying hand, literally, during turning to suppress chatter and maintain stable machining, while it can also carry a coolant nozzle to accurately direct fluid at a moving cutting zone.

Described as a ‘super fusion built-in robot’ packaged in the work chamber of a smart machine, the company says it lets operators use its innovative robot operating system to operate the unit using wih normal machine tool-like control, without requiring teaching, to achieve innovative automation and productivity.

Machine & Robot working together

It boasts three key features: collision-free working zone integration allows for robot motion in the work chamber during machining, which is impossible with conventional robots; high level applications support previously provided by expert machinists can be delegated to well-coordinated machine and agile-robot operations; and there are three types of end-effector stored, with the robot able to change between these, according to the application.

For use with machining centres, Standroid avoids the conventional separate machine tool and robot control systems. Designed to be a ‘teaching-less’ robot, the Standroid is equipped with a global-first Robot Operating System (ROS) that enables the operator to handle it safely and with the same ease as that of operating a machine tool.

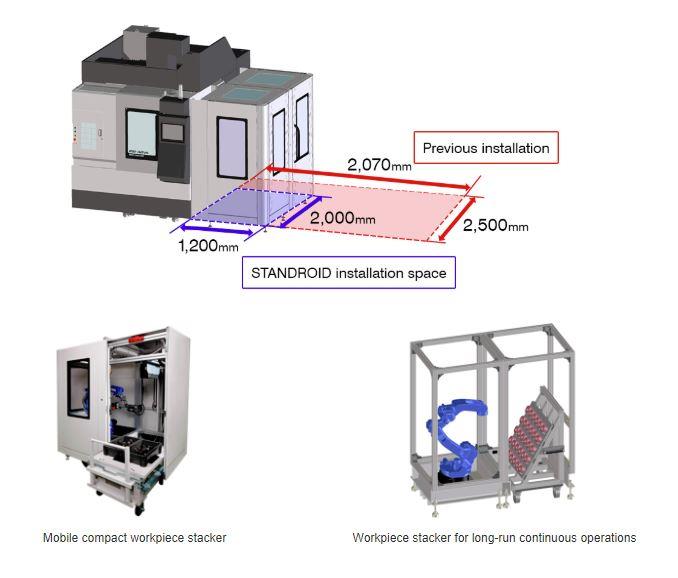

The Compact Automated Cell (CAC) package includes all the equipment required to easily build and implement an automated space-saving system, without relying on system integrators.

The robot, workpiece stacker and other related equipment are minimally packaged in a space of only about two pallets – the need for more space and a safety fence are both negated.

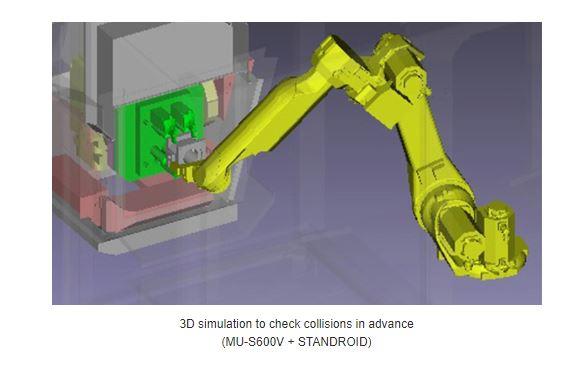

Three key elements highlighted by Okuma are: even if the workpiece or mounting position is changed, the part-program can be changed with only a setting change; Standroid can be manually operated with the pulse handle or the jog feed button of the machine tool; and collision-free control assures safe and smooth operations in a compact automated cell, with start and end points of motion input by interacting with the CNC operation panel and Collision-Free Control automatically creating the shortest non-interfering routes in a tight space for easy operating confirmation.

The machines are not confirmed as available in the UK as yet. NCMT is the UK agent.