Tongtai, which is represented in the UK by Matchmaker CNC, is a Taiwanese-based machine tool maker of primarily 3- and 5-axis vertical machining centres. Subsidiary brands include Honor Seiki, Asia Pacific Elite, QuickTECH Machinery and Shuzhou TongYu Machine & Tool. The manufacturer, which went public in 2003, is predominately Asian in sales; in its fiscal 2015, 72% of its sales were in Asia; 46% in China, 13% in Taiwan and 13% in other Asian countries. Its 2015 sales turnover was €185 million. Automotive is its biggest industry (44%); others include aerospace and medical industries.

In April 2015 it bought French firm PCI SCEMM, which specialises in high-speed machining centres and transfer machines, from automotive OEM the PSA Group. PCI sells direct into the UK; recent sales include a cylinder head machining line for Montupet UK at Belfast and a cylinder block line for Ryobi Carrickfergus (both are near Belfast).

Two months later, Tongtai acquired 76% of the shares of holding company MBI-Group. It consists of Austrian machinery manufacturer Anger, which specialises in special machines for transmission manufacturing, and multi-spindle head and machine tool component manufacturer Hellmerich.

All three companies continue to be run as independent brands.

Anger’s Tamara Dekum says that the move was of great benefit to her medium-sized employer, whose large projects of perhaps €15 million for automotive Tier 1s often proved difficult to finance. As a result, it had been looking for a strategic investor.

Product ranges are complementary; in automotive, Tongtai is more focused on chassis components and Tier 2 or 3 suppliers, especially in Asian markets, so it benefits from access to the higher echelons of the European automotive industry, while PCI and Anger benefit from a worldwide sales and service presence thanks to Tongtai’s international dealers.

In Europe, Tongtai is looking to work with Anger and PCI on turnkey solutions, because they are difficult to offer through dealers, and because they are popular with automotive OEMs.

For Anger and PCI, Tongtai creates a richer context for specific solutions. Dietmar Bahn, a Hellmerich executive and now in charge of Tongtai Automotive Group strategic development, says: “We want to offer all-round machinery solutions that will be of interest in the long term, alongside the Tongtai Group’s extensive portfolio of machinery. In return, we get to benefit hugely from the constructive and collaborative partnership within the group.”

Adds Dekum: “Our aim for the future is that we can integrate solutions from the whole group into one solution; for example if Daimler would need a special machining transfer centre from Anger, but also wants to have a standard machine from Tongtai in one lane, [we would supply that] and maybe in future we will do integration of the whole thing too.”

As far as joint engineering projects go, Tongtai and PCI are developing a new machine, said to be a “cost-effective, single-spindle machining centre for different automotive applications.”

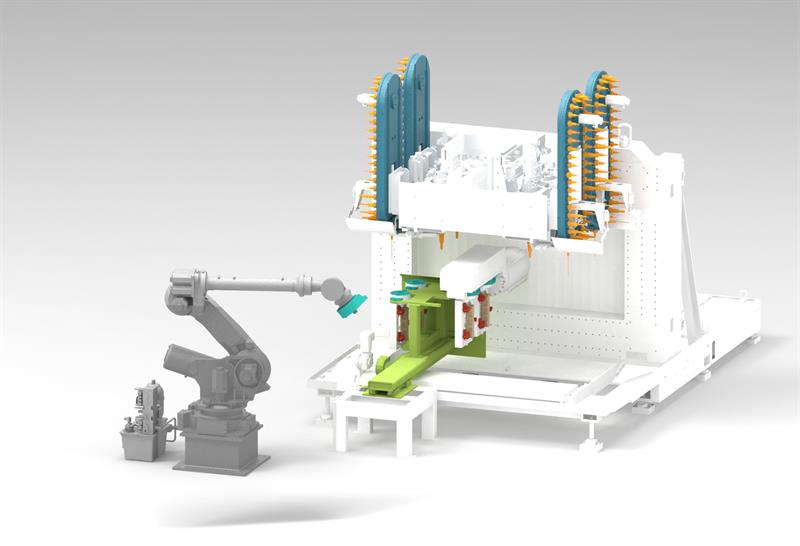

Anger's robot loading system

At AMB, Anger promoted a universal robot arm and machine table interface that it has developed to handle different parts or operations in one machine without needing manual retooling. The robot picks up an Anger clamp via a universal interface. The clamp also serves as gripper and picks up the raw part. The robot places the clamp with part in a shuttle that loads the machine. Held by the universal interface, clamp and part are transferred within the machine to the table. In this way, the machine can be flexible enough to accommodate varying quantities of production runs, or changes in parts, which only require changes to the clamping fixture.

Tongtai VU-5

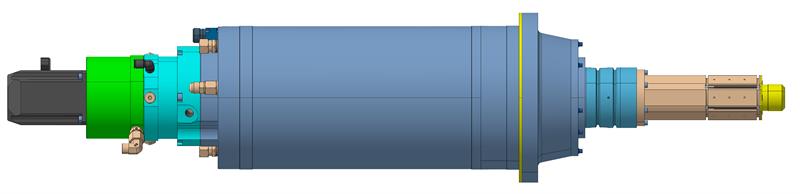

And Tongtai presented the VU-5 5-axis mill with ultrasonic generator intended for use refinishing hard or brittle materials in opreations such as valve deburring, polishing and surface finishing; a quality of 2 micron is promised. The unit achieves vibration frequency of 15-45 kHz and spindle speeds up to 24,000 rpm.

UPDATED 13:30: Corrected PCI spindle picture caption; altered recent PCI orders; added a second PCI picture